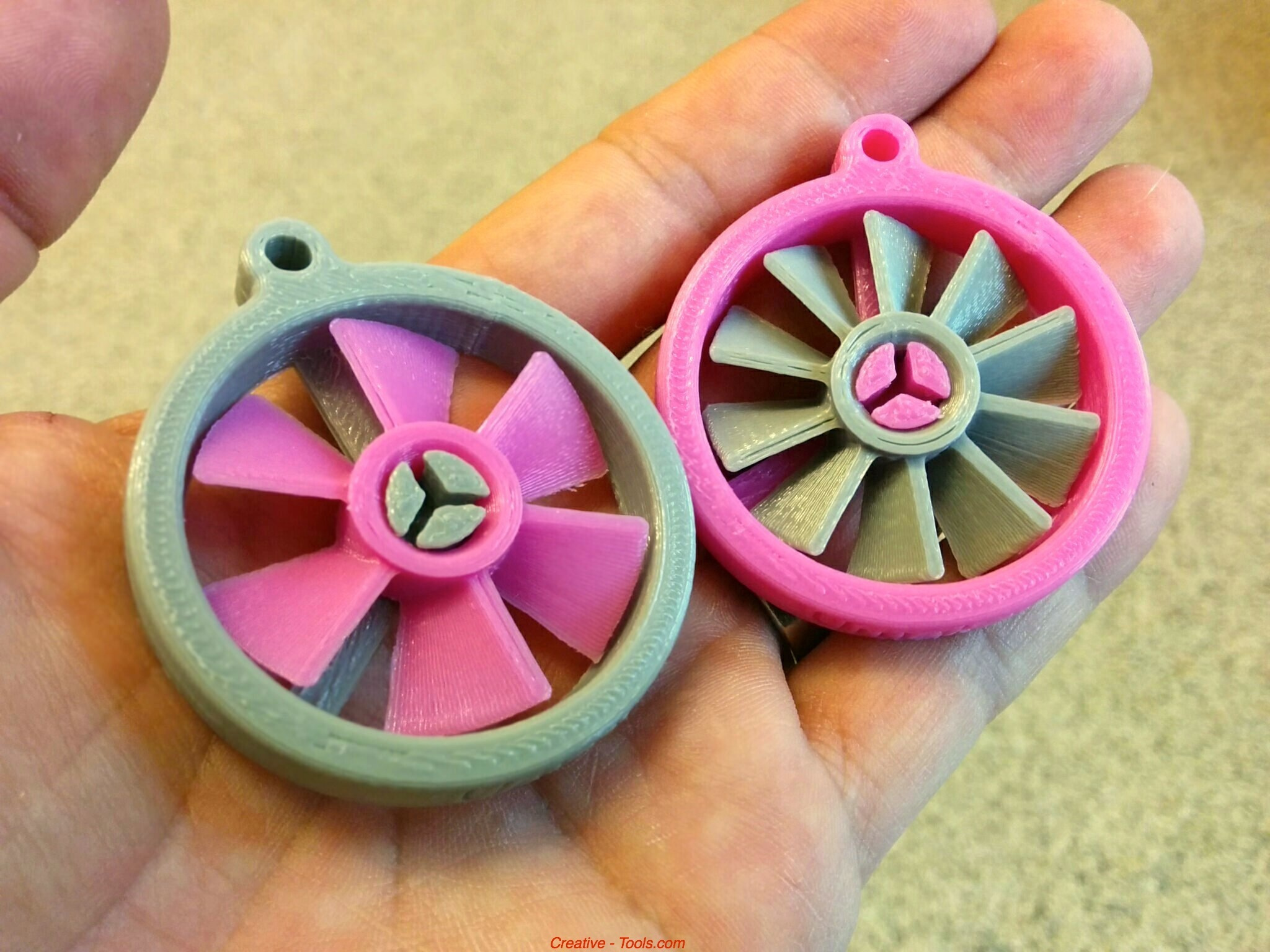

When it comes to a potentially world-changing technology, there are only a few examples in the modern world as effectual and realistic as 3D printing. This technology has been in use for quite some time in certain industries, but it’s only just now growing to the point that it’s reaching the mainstream of scientific development. Industry innovators are starting to see the potential for 3D printing in hundreds of applications, and there seems to be no stopping the industry from advancing.

One of the most prominent areas of the 3D printing market is the development of new materials that can be used as substrates for advanced 3D printers. Metallic elements and some plastics are already standard in 3D printing, but new materials are constantly being added to the repertoire of 3D printing enthusiasts. If you are interested in 3D printing, check out some of the newest developments in the materials used for the process.

Extraterrestrial Materials

Scientists who are looking into the far future have developed a 3D printing material based on martian and lunar dust. This material will provide future explorers with the ability to create structures or objects from the limited resources in those extraterrestrial environments.

Northwestern University and its McCormick School of Engineering are responsible for the initial development of this material, which is actually a simulated martian dust similar to the type used by NASA for testing its own technology. Assuming the source material is similar enough, the same techniques will work with the lunar and martian dust found outside of Earth.

Objects made with this dust material aren’t rigid and inflexible as you might think, but instead, they are elastic and rubber-like. After the material has been 3D printed, it can be folded, cut, and otherwise manipulated to serve just about any purpose. It is even possible to harden the material into something closer to ceramic using additional heat.

Glass

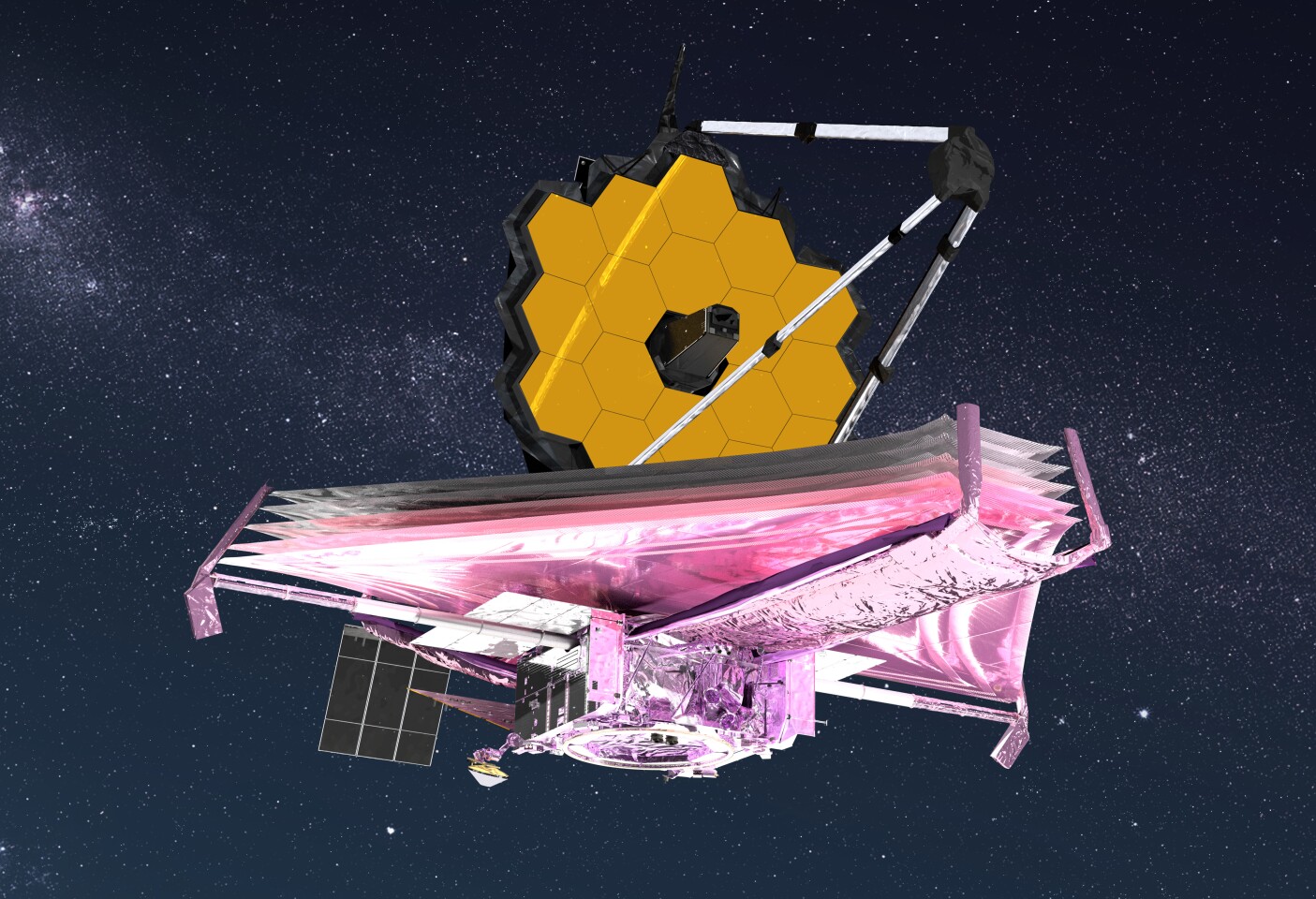

Glass has been a 3D printing material for some time thanks to a process developed by MIT in which molten glass is extruded to form a new shape. Recently, a team from Germany at the Karlsruhe Institute of Technology has pushed the technique to new levels by developing a 3D printing solution that uses glass of optical quality. By using this material in additive manufacturing situations, new applications for glass as a substrate will open up to the scientific world.

Since the glass maintains its optical quality after printing, the possibility of data transmission and visual optics using the material and objects made from it is very real. To create glass of optical quality for 3D printing purposes, liquid polymers are used to create a matrix of quartz glass nanoparticles. Using stereolithography, the material is cured using light in much the same way that a composite tooth filling is instantly cured using UV light when filling a cavity. A solvent is then used to cleanse the cured object of any remaining liquid material. Once the final object is cleansed, it undergoes extreme heat to remove the polymer that brought the quartz nanoparticles together in the first place.

Flickr CC/fdecomite

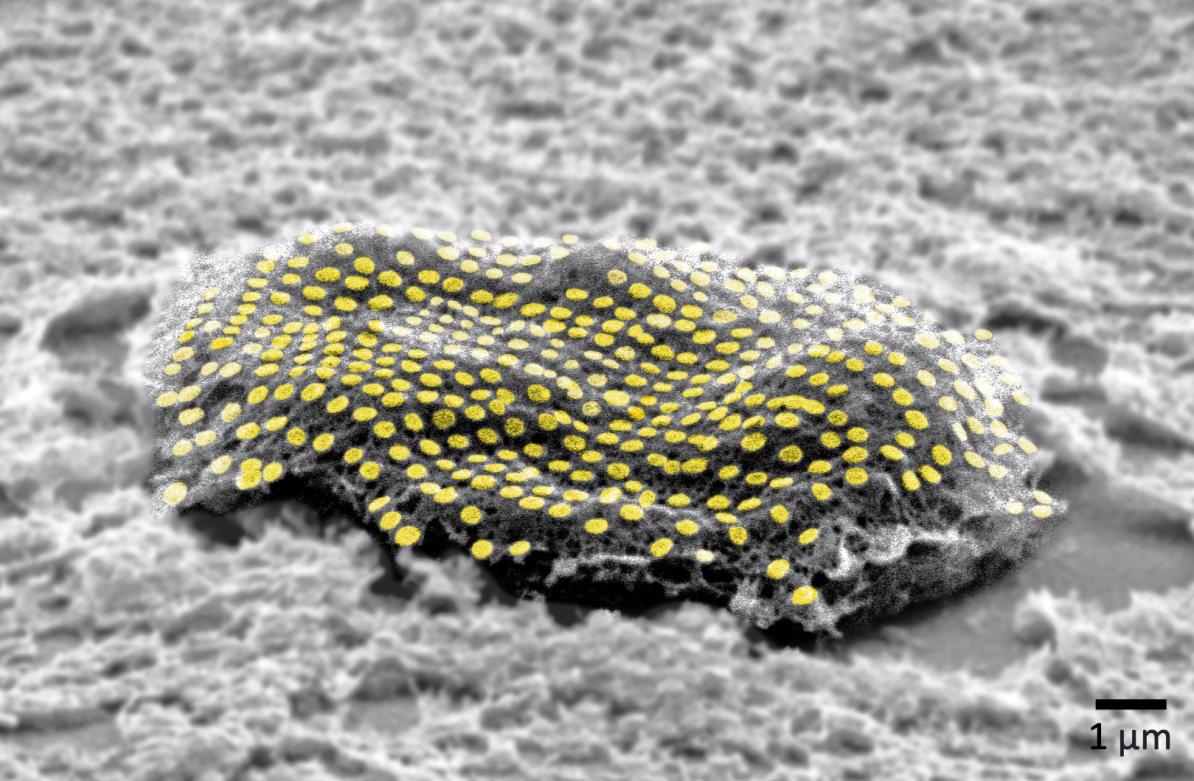

Bacteria

Most people probably wouldn’t consider bacteria to be a good material for 3D printing, but in an industry where material waste is a big issue, no material can be ignored. When compared to 3D printers, standard CNC machines have more advantages and still control the majority of the manufacturing processes in the modern world. However, CNC machines are very wasteful. On the other hand, 3D printing has the ability to forego that waste by only using what is necessary.

One group of researchers from the Delft University of Technology is working toward a range of materials that rely on bacteria to produce biodegradable and sustainable materials for 3D printing. Using advanced technology and methodology, those researchers have developed a way to use bacteria in the 3D printing process, and they are just getting started with the applications for the technology. Some experts believe this bacteria-based technique could be used to produce graphene, one of the most powerful and thinnest compounds known to man.

Hydrogel

It might come as a surprise that 3D printing can potentially be used to produce replacements for complex organs and other bodily components, but that is exactly the direction the health industry is heading. Researchers at Duke University have already developed a 3D-printed replacement for cartilage, and it is being used to help surgeons create knee replacements and other joint components that are similar to the natural cartilage found in those places.

These materials are called hydrogels, and they have a structure that mimics that of a natural cartilage. They’re built of long polymer chains filled with water, and they are completely stable inside the human body. They exhibit the same elasticity as normal cartilage, and they are just as strong. Using a consumer-grade 3D printer, researchers were able to produce perfect menisci for a model of a knee that was meant to be used as a test for the technology.

Final Thoughts

3D printing will be a foundation-level technology for the future of man because of its incredible potential and vast variety. The ability to print anything from a full building all the way to a functioning human organ means that 3D printing will only continue to advance until it is either perfected or replaced by a better technology. One can only imagine what sort of miraculous technology from the future could replace something as useful as a 3D printer.

Author Bio:

Heather Redding is a tech enthusiast and freelance writer based in Aurora, Illinois. She is a coffee-addict who enjoys swimming and reading. Street photography is her newly discovered artistic outlet and she likes to capture life’s little moments with her camera. You can reach Heather via Twitter.