Welding is one of the most common fabrication processes in the world. In fact, in your immediate vicinity is probably several things that were welded together. Many people learn how to weld either for work or as a hobby. You’ll likely encounter MIG welding when you start learning how to weld. Below, we’ll explain the process of MIG welding along with the metals you can use with this process.

What is MIG Welding?

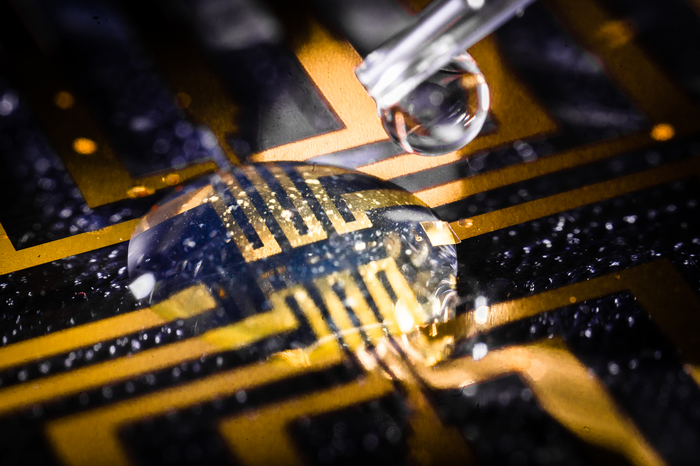

Welding is essentially fusing two pieces of metal. There are many methods for welding metals together, one of them being MIG welding. MIG welding, or Metal Inert Gas, is a type of Arc welding and one of the most common types of welding. In this process, you’re heating the two metals with the help of an arc. The arc forms between the welding surface and a continuously fed filler electrode.

When you weld with MIG, you use a MIG welding gun. This tool features several components: a control switch, a contact tip, a gas nozzle, a shielding gas flow, and electrode conduit and power. As you pull the trigger on the welding gun, an arc forms between the end of the wire electrode and the piece you’re working on. It’s this arc that melts both the piece and the wire, which forms the weld pool.

MIG Welding Aluminum

One of the easiest metals to weld with MIG is aluminum. When choosing your aluminum, make sure you know the grade of the aluminum, which ranges from the 1000s to the 6000s, as this indicates the purity level and can impact your project and the welding process. For example, aluminum on the lower end of the scale is typically easier to weld, while those in the 6000 range require much more effort and extra filler material. However, it’s not a linear scale, as aluminum in the 2000s is much less weldable and is often unused in welding.

If you’re going to weld with aluminum, you should consider using an aluminum alloy. This will give you a stronger material than aluminum; however, you’ll have to be extra careful about the temperatures you use while welding. Think carefully about the type of aluminum you want to use and its grade before starting your project for the best results.

MIG Welding Stainless Steel

Stainless steel is one of the most common metals in manufacturing; therefore, it’s not surprising that it’s also one of the most common welding materials. The reason that stainless steel is so popular is because of its corrosion resistance and durability. If you’re making something that needs to stand up to corrosive materials or moisture, like kitchen knives, stainless steel is a great option.

Three types of stainless steel are ferritic, martensitic, and austenitic. These types play a big role in how easy it is to weld with stainless steel. Austenitic and Ferritic are very easy to weld, which is why they are used the most often. On the other hand, Martensitic is much harder and more difficult to weld with, and it has a higher likelihood of cracking, which makes it not ideal for welding. To MIG weld with stainless steel, you’ll want to do plenty of practice, as it requires a great deal of technique and knowledge.

MIG Welding Low Carbon Mild Steel

Low-carbon mild steel is affordable and easy to access, making it a popular choice for beginners and experienced welders. If you’re just learning how to MIG weld, this can be a great material to practice due to its relatively lower costs. Not only that, but low-carbon mild steel has many applications, so you can try out your welding skills on various projects. For example, you may use low-carbon mild steel on things like fencing, car parts, kitchen cutlery, and building parts like frames and pipelines.

Low-carbon mild steel is great at preventing brittleness, and you typically don’t have to worry about hydrogen cracking. This is one of the primary reasons it’s so widely used, from manufacturing to engineering to scientific equipment. If you want to learn a type of welding that can be used in a wide range of applications, consider learning to MIG weld low-carbon mild steel.

MIG Welding Copper

Copper is one of the more pliable metals on this list, and it’s softer than both stainless steel and low-carbon steel. One popular application for MIG welding copper is in artwork. For those of you that want to put your welding skills into more creative pursuits, this may interest you. If you’re going to MIG weld copper, you’ll want to preheat your welding gun sufficiently before you start. This is because Copper can conduct a lot of heat, so you’ll need a high temperature before you can start to weld the material.

However, you also run the risk of thermal expansion with Copper if you aren’t careful. If this happens, you may experience distortion within your metal. This is why we often use a copper alloy instead, where it’s mixed with elements like lead or selenium.

MIG Welding Cast Iron

Finally, there is cast iron. We saved this one for last because it’s one of the most difficult metals to work with. There are three types of cast iron: ductile iron, white iron, and gray iron. Gray iron you can work with if you put in enough effort, but white iron is practically unworkable. Ductile iron is pretty rare and a slow process, but you can work with it. Because of this, you’ll work with the most common type of cast iron gray iron. And while you can MIG weld with cast iron, you may be better off using TIG welding as it’s better at handling the difficulty of cast iron.

Getting Started with MIG Welding

If you’re new to MIG welding, we recommend starting with some of the easier and more accessible metals. This will give you good practice with the MIG welding process and tools. Once you start to gain a better understanding of how MIG welding works, you can move on to tougher projects and more complicated metals. We hope this guide was able to shed some light on the uses for MIG welding and the types of metals you can use it with.