GGB Bearing Technology: A World of Bearings

One of the most important mechanical inventions of all time was the wheel because it lessened the force of friction involved in movement. Bearings, based on the wheel, laid the groundwork for the Industrial Revolution.

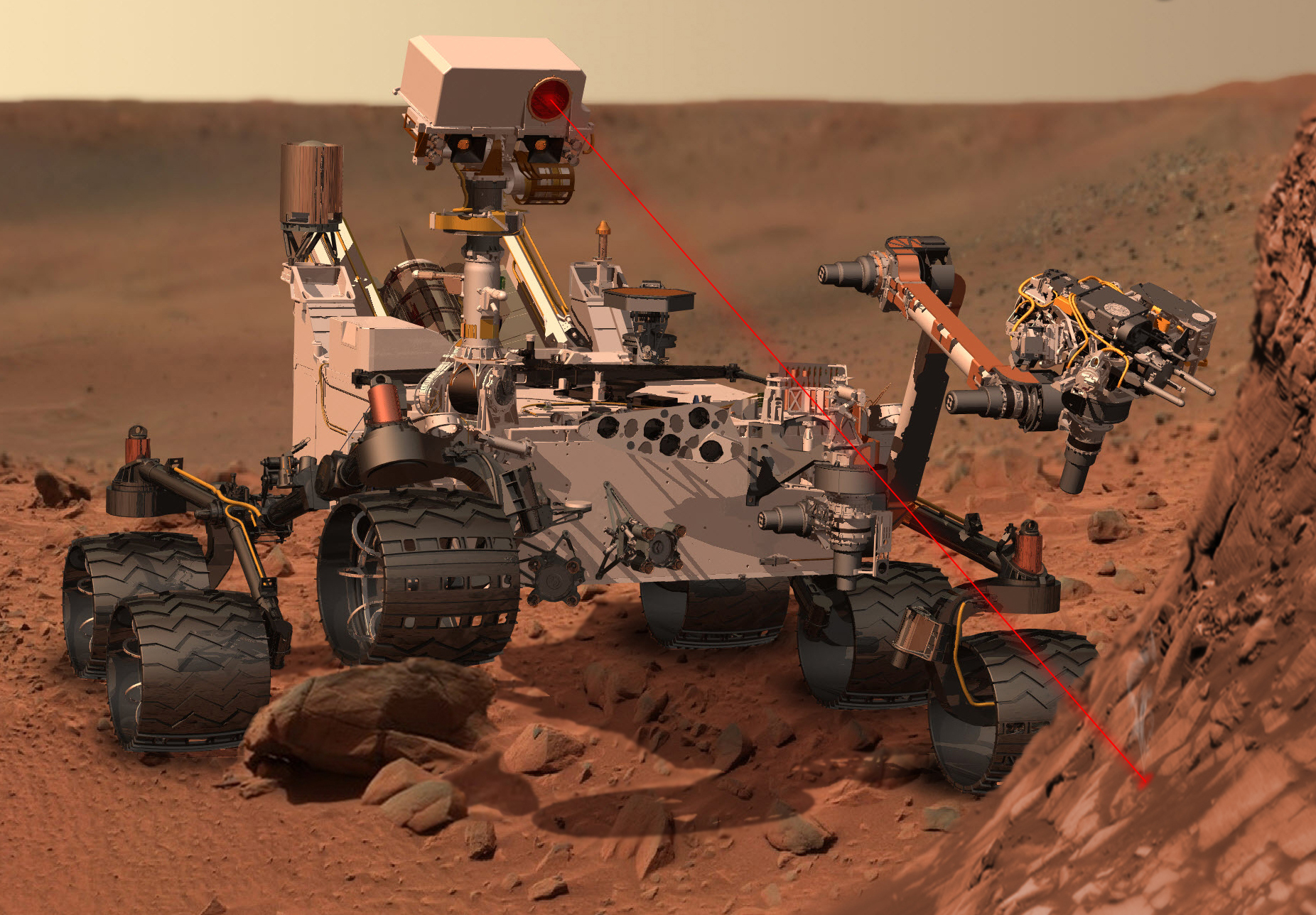

Bearings manufactured by GGB Bearing Technology (formerly Glacier Garlock Bearings) are critical to NASA’s Curiosity mission. GGB’s DU® metal-polymer bearings are key components in the drill that Curiosity is using to sample rocks in the Martian landscape. Earning the trust of NASA has taken decades of experience and success in industries including aerospace, agriculture, automobiles, chemicals, construction, consumer products, hydraulics, industrial equipment, lifting, machine tools, marine, medical and office.

Innovative New Two-Piece, Double-Flanged Solid Polymer Bearings

Called FLASH-CLICK™, the new bearings feature a special geometry for easy manual or automated installation without the need for pilot or assembly tools. The bearings are available in all nine of GGB’s EP™ series of lightweight, corrosion-resistant solid polymer materials, which provide low friction, long wear and noiseless operation. These properties, coupled with the bearings’ innovative design, make them suitable for replacing more costly bearings in many applications, such as monitor hangers, adjustable medical lamps, convertible tops, and automotive seats.

Adjustable automotive seat mechanisms have multiple pivot points that require bearings for smooth operation. The loads can be high, depending in part on the passenger’s weight. Wear resistance and low constant friction are required, which is particularly important with electrically driven systems. The new FLASH-CLICK™ bearings perform well in this type of application. Their two-piece construction simplifies installation, and they also reduce total system costs by allowing bearing housing tolerances to be reduced.

FLASH-CLICK™ bearings can be supplied in virtually unlimited custom dimensions, pending project-related feasibility checks. They also can be supplied in multiple sections for creating longer bearings. For more information contact usa@ggbearings.com.