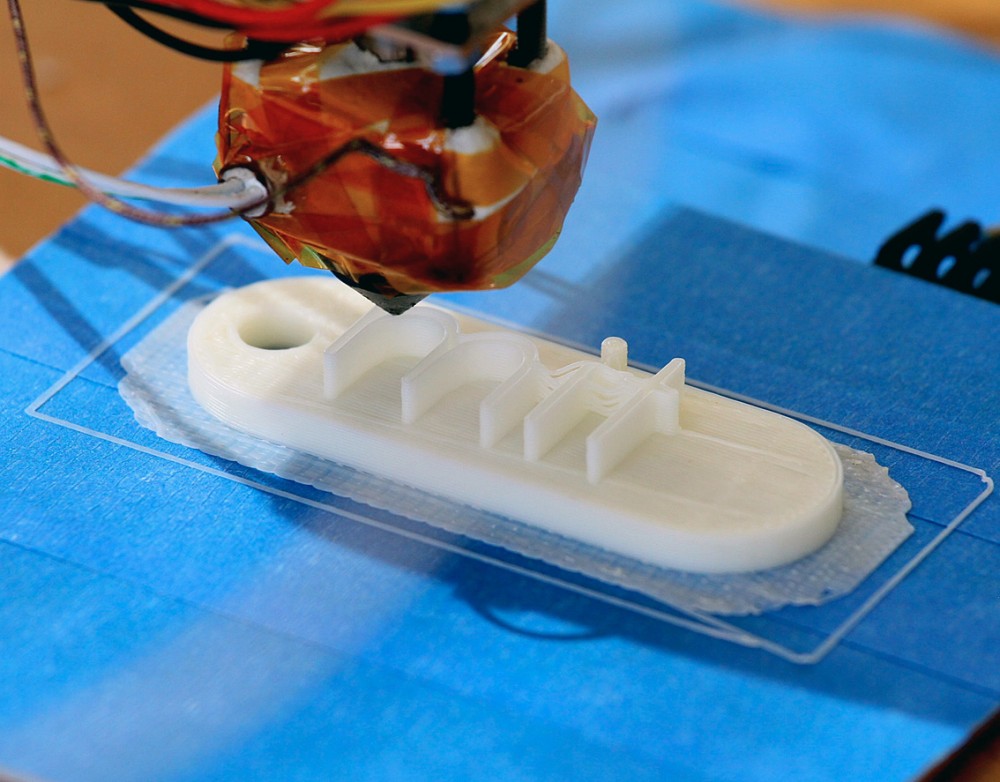

A New Multi-Material 3D Printing Paradigm

MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) has developed MultiFab to improve upon current 3-D printers that typically use one or two materials as well as current multi-material printers.

MultiFab not only allows 10 materials to be printed in one print, but the platform is also low-cost, contains easily reconfigurable hardware and software, and is primarily intended to support novel research and manufacturing not currently possible with existing multi-material printing platforms. This kind of multi-material 3-D printer allows for significant experimentation by combining materials that interact in novel ways both mechanically and optically.

MultiFab is a modular, scalable, high-resolution printer architecture with an integrated machine vision system. According to MIT News, “this system allows for self-calibration of printheads, 3-D scanning, and a closed-feedback loop to enable print corrections.”

Main Features of MultiFab

MultiFab features:

- Enable 3-D printing of parts with materials that interact optically and mechanically.

- Have modularity allowing modules to be added and removed as required in specific applications.

- Low-cost hardware that is built from off-the-shelf components and has a Bill of Materials (BOM) of about $5,000.

- Printing in high resolution of sub 100 µ for all materials and can print from hundreds of microns to tens of centimeters.

- Piezoelectric printheads that enable multi-material 3-D printing with a resolution of at least 40 micrometers [mu]m and enables mixing of materials at the micron level.

For more information on MultiFab see the paper.