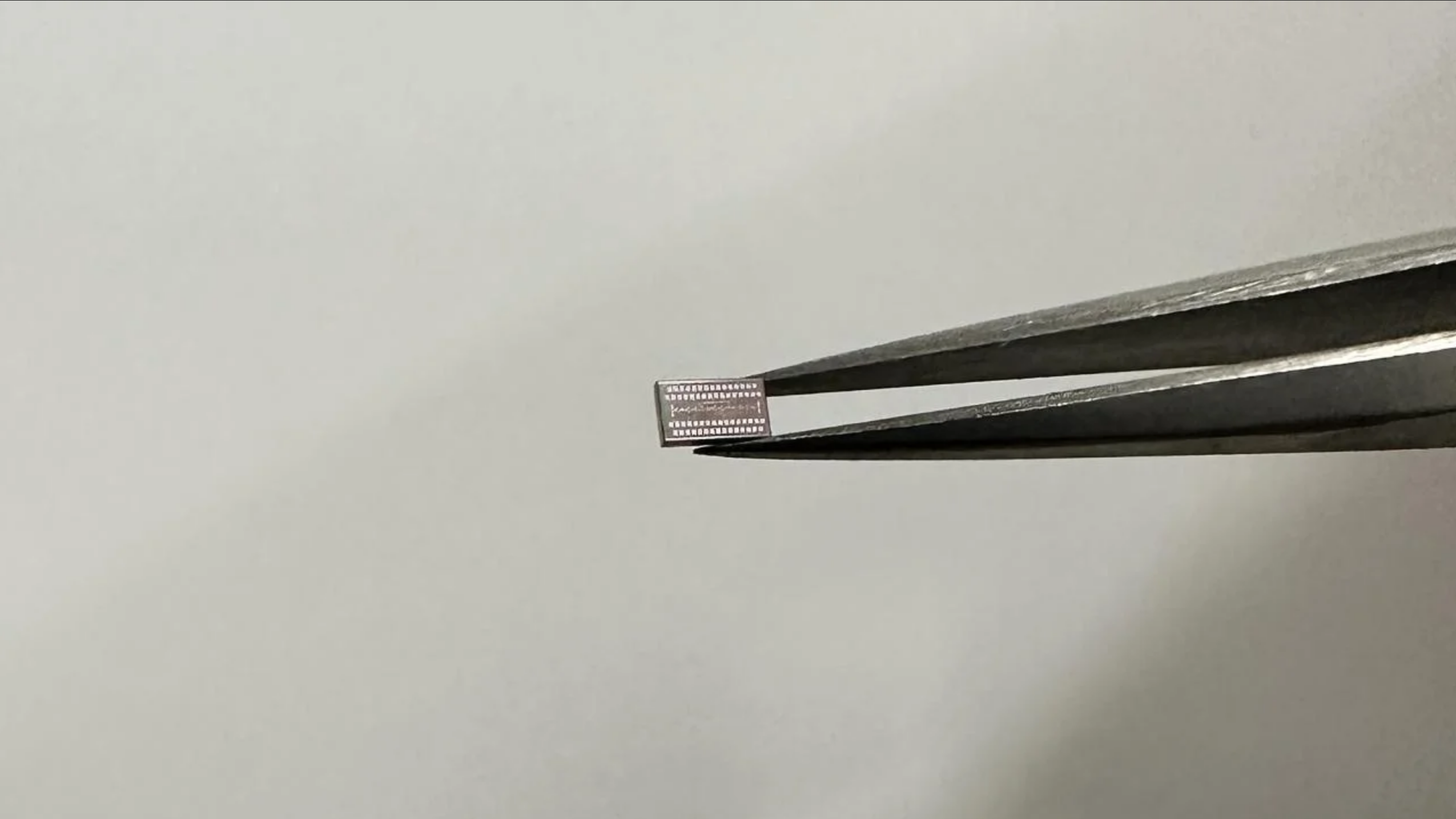

Numerous industrial automation applications, such as quality assurance, inspection and measurement, depend on machine vision sensors that utilize optical filters to improve their effectiveness by filtering out undesired wavelengths of light while letting desired wavelengths flow through.

You can improve the efficiency of your machine vision sensors by picking the right optical filter. However, to select the right optical filter, you must be aware of the different kinds of optical filters that are available.

Optical filters function by selectively transmitting or rejecting specific wavelengths of light, allowing only the selected wavelengths to pass through. They are composed of glass, plastic or metal, and can be tailored to block a particular wavelength or range of wavelengths.

Different Types of Optical Filters

Bandpass filters are one of machine vision sensors’ most frequent optical filters. These filters allow a particular spectrum of wavelengths to pass while suppressing all other wavelengths. Bandpass filters can be utilized in applications involving the detection of specific colors or wavelengths, such as product packaging inspection or identifying faults in electrical components.

The extended pass filter is another type of optical filter that is often employed in machine vision sensors. These filters allow longer wavelengths of light to pass through while obstructing shorter ones. Longpass filters are beneficial for applications that require sensing light in the infrared spectrum, such as thermal imaging.

In contrast, shortpass filters block longer wavelengths of light while allowing shorter wavelengths. They are useful for applications that require UV light detection, such as the inspection of medical equipment or semiconductor wafers.

Exploring Neutral Density Filters

Neutral density filters are a distinct sort of optical filter found in machine vision sensors. These filters diminish the intensity of light without changing its color or wavelength. Neutral density filters are useful for applications that demand precise light intensity measurements, such as display inspection or luminance measurement.

Specialized optical filters for specific applications are available in addition to these common types of optical filters. Polarizing filters, for example, can be used to eliminate glare and reflections. Color filters, on the other hand, can heighten the contrast between distinct shades.

Factors to Consider While Choosing the Right Optical Filter

When choosing an optical filter for your machine vision sensor, numerous things must be considered.

- One of the most important considerations is the spectral range of your sensor. To achieve the best performance, you must select an optical filter that matches the spectral range of your sensor.

- Another critical factor to consider is the filter’s transmission properties. Some filters may have robust transmission in the required wavelength range but low transmission in other wavelengths, limiting overall brightness.

- The angle of incidence is also a critical component to consider, as some filters may have a limited angle of incidence, resulting in reduced effectiveness if light strikes the filter at an angle.