The world’s first 3D-printed spacecraft thruster with a platinum combustion chamber and nozzle recently successfully passed a heavy test that included an hour of firing and more than 600 ignitions.

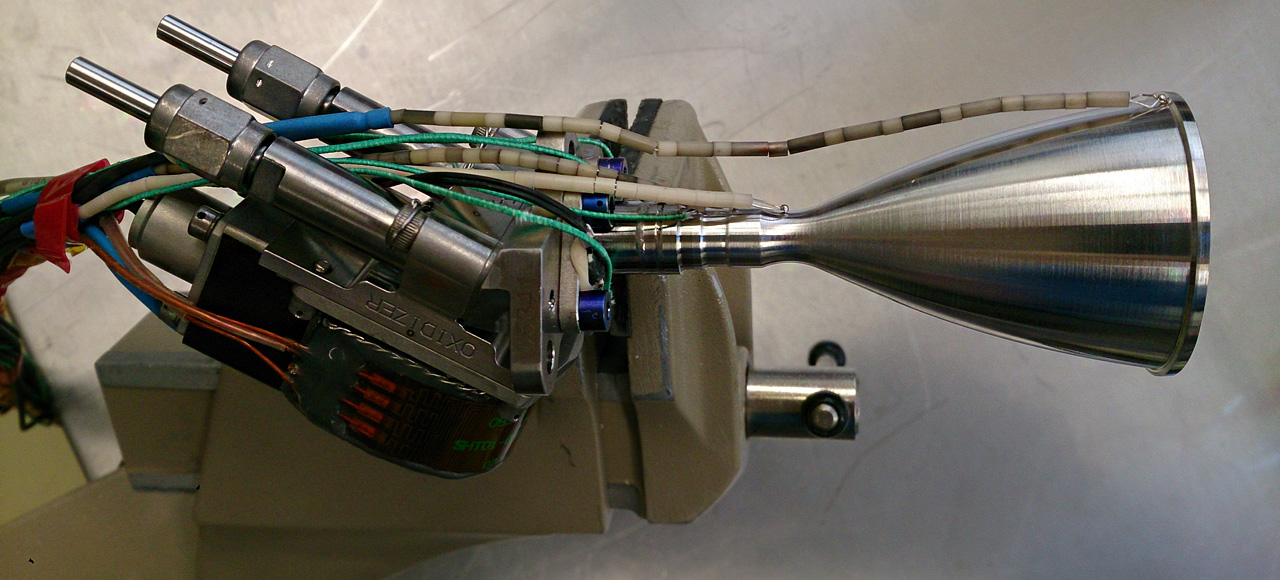

In the image above, you can see the finished product of the 10 N hydrazine thruster which was printed in platinum—rhodium alloy using a laser beam applied to a metal powder bed.

The 3D-printed spacecraft thruster was created and tested at the Airbus Defense & Space facility in Lampoldshausen, Germany, as part of the ESA’s Advanced Research in Telecommunications Systems program, ARTES.

Manager of the project, Steffen Beyer, says, “The firings included a single burn of 32 minutes, during which a maximum throat temperature of 1253°C was attained. It demonstrates that performance comparable to a conventional thruster can be obtained through 3D printing.”

“The aim was to test this alternative manufacturing method as a way of reducing material costs. At the start we were by no means certain it could be done, or even whether the metal powder could be prepared to the appropriate quality. For production we ended up using a laser machine normally employed for making jewelry, which is the current industrial state-of-the-art for manufacturing with these metals,” explains Laurent Pambaguian, ESA supervisor.