RWM Casters Co. is the originator and recognized market leader of the Kingpinless caster in the United States.

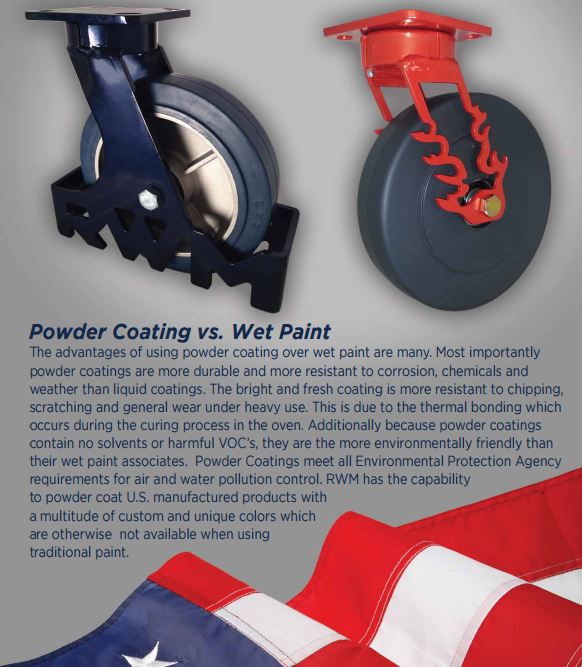

Never satisfied and always pushing the envelope when it comes to product innovation, RWM has implemented powder coating as a standard on U.S. manufactured industrial caster products.

Reasons For Changing From a Liquid to a Powder Coat Finish:

- Powder coating is much more durable.

- Liquid paint more easily chips and peels off after heavy use.

- Powder coating can withstand the everyday wear and tear of heavy duty use.

- It can endure chemicals, weather and is less prone to corrosion than a liquid or zinc plate finish.

- Powder coating is an environmentally safe application. It does not release harmful VOC’s or solvents into the air.

- Powder coating meets all the requirements put forward by the Environmental Protection Agency for water and air pollution.

Those who work closely with RWM have known powder coating as an option for some time, and because of its benefits regarding both the environment and the workplace, it made sense as the new standard.

At RWM, the powder coat finish standard is applied to the company’s heavy duty industrial caster series. These series include the 75, 76, 85, 95, & 125 series of Kingpinless heavy duty casters, as well as some of our other popular series. If you need a specific design, RWM has the capabilities of producing special colors which can be applied to both custom and standard caster designs.

What You Will Notice:

1. Top of the line quality

2. Outlast both wet paint and conventional Zinc finishes

3. Offered standard at no additional charge on many series

4. Premium appearance with a multitude of finish options