Winsonic Marine grade LCD Displays / Panel PC with aluminum front bezel are suited for the harshest environments. Winsonic incorporates many unique features to add more functionality, including IP65 Front water resistance, anticorrosion, and isolated 9-36V DC wide voltage input. These units are suitable for a wide variety of military and commercial marine applications. Full-range product sizes from 10.4” to 24” for Marine Chassis and Marine Flush Mount enclosure are available. Customization is also available to suit any customer’s needs.

Features:

• Wide dimming adjusting through PWM control (Optional for Panel PC)

• 6mm Aluminum, anodized Flush Mount front Bezel

• IP65 front

• Housing with powder coating design

• Anti-Salt

• Anti-Corrosion

• Protected glass, touch option

• Isolated 9~36VDC wide voltage input

• Anti-Shock and Vibration enhanced

• Removable Stand

• Wide Viewing angle option

There are several state-of-the-art technologies applied in Winsonic Marine Product Series.

Wide Voltage Input

The supply of voltage can be unstable in marine applications. The wide voltage range input solution in Winsonic Marine Products can reduce possible damage due to unstable voltage from the power generator on a boat, thus increasing the reliability of the whole system dramatically.

Sometimes, different applications appear unstable as a result of no suitable power to fit the appliances. Incorrect voltage and current may also damage the electric components. Our wide voltage range power input solution is designed accordingly to solve the problem and to protect the products by converting different voltage input to meet the one required. We provide several kinds of DC to DC converter power modules fulfilling full range of both LCD display and embedded system demands.

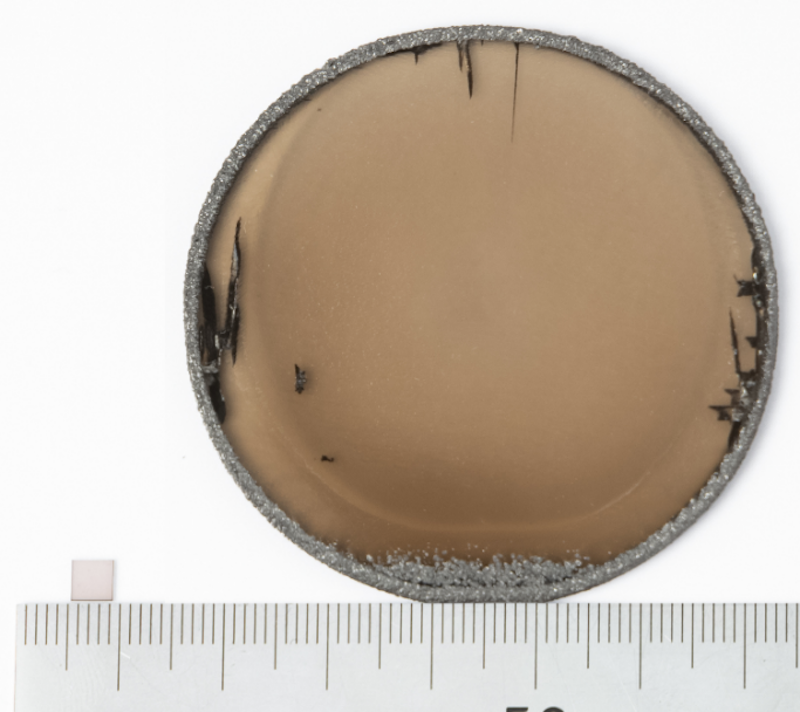

Conformal Coating

Conformal coating material is applied to electronic circuitry to act as protection against moisture, dust, chemicals, and temperature extremes that, if uncoated (non-protected), could result in damage or failure of the electronics to function. When electronics must withstand harsh environments and added protection is necessary, most circuit board assembly houses coat assemblies with a layer of transparent conformal coating rather than potting with the UV light inspection. Winsonic can ensure the full coverage of the coating.

Anti-vibration

Anti-shock and anti-vibration technologies are crucial for meeting the demands of the harsh application environments. Winsonic has developed several technologies to withstand vibration and shock, enabling Winsonic Marine Grade products to perform great in the anti-vibration, anti-shock testing.

How Does It Work?

1. Shock and constant vibration are prone to cause malfunctions of certain components, like capacitors or big components. With additional adhesive on these components, the durability of the components increase and the chance of failure reduced.

2. The right choice of high quality components, high tech material, and mechanical design is our core competence. Of course, related know-how about the assembling, connecting, and mounting is a necessity too.

Benefit

With the Winsonic optimized mechanical design, and the careful selection of high-tech materials such as butyl rubber and high damping silicone, Winsonic is able to provide a series of the Marine Grade Products which are compliant with the certifications for the specific application.