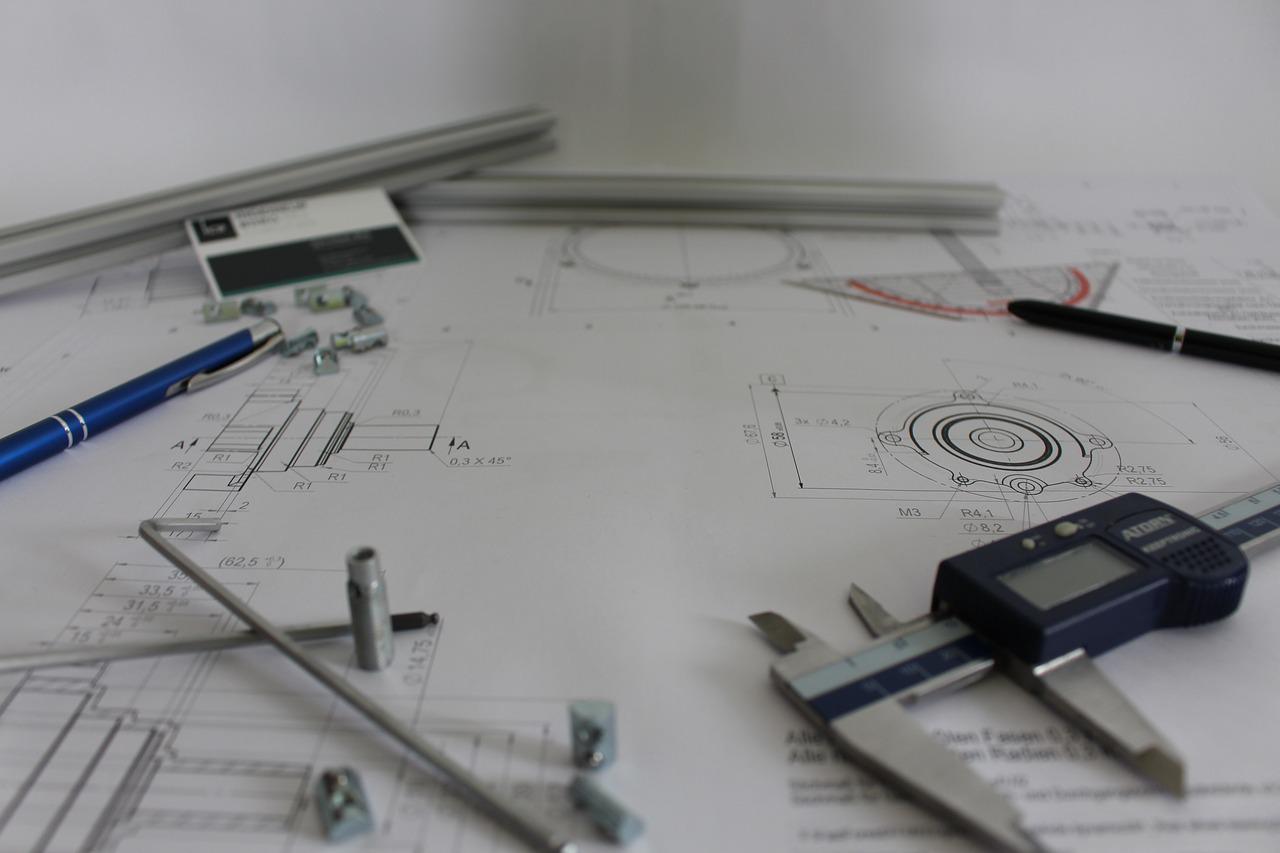

In manufacturing, the most important part is to make the component according to the required dimensions and tolerances so that it fits perfectly into the assembly and functions properly. Most of the waste parts in the industry are produced as a result of the wrong tolerances and dimensions. These waste parts are a huge loss for the manufacturing industry as the material and machining costs go wasted. To make the machining accurate in terms of tolerances and dimensioning, engineers need to follow certain standards. Mostly the standard that is used worldwide is the ASME standard of Geometrical Dimensioning and Tolerance. Using these manufacturing standards, the loss of material, cost, accuracy, precision, and time can be reduced significantly.

The GD&T has allowed the world to manufacture components with the same dimensions as it is a universal standard. Therefore, if a person buys a radiator for his car from anywhere in the world it would be of the same dimensions as the whole world is now following the same standards of GD&T. The ASME standards of geometric dimensioning and tolerances also provide a complete guideline for the characters, symbols, language and tools used in the manufacturing process. Therefore, the engineers now have a complete book of guidelines for all their manufacturing processes for manufacturing any engineering component.

When engineers follow the standards of GD&T while manufacturing different components in the industry, there are many advantages they obtain. A few of these advantages are listed below:

1. Accuracy and Precision

Using GD&T standards, engineers and manufacturers obtain the parts that are more precise and accurate. These parts, when fit together in an assembly, have a more accurate performance and functioning. For example, the shaft and key made according to GD&T standards work more accurately when the shaft is rotated in the working environment. On the other hand, shafts made without GD&T standards are more affected by vibrations and torsional stresses.

2. Universal Communication in Manufacturing

As the ASME standards of GD&T are used worldwide for manufacturing in the industry. Hence, the components manufactured from any industry in any part of the world are producing the components with the same dimensions and tolerances. Hence, these components can be assembled, reassembled, or repaired anywhere in the world. Also, engineering drawing has become similar throughout the world, and they can be read and understood all over the world because GD&T provides the same drawing methods, language, symbols, and characters.

3. Ease in Manufacturing Processes

GD&T has made manufacturing much easier than before. GD&T provides the values of tolerances that are allowable and in between these tolerances, the parts are suitable for a particular assembly. For example, the GD&T provides information that a particular rivet will fit in the hole of diameter having a tolerance of 5.5 inches to 5.66 inches. So, the manufacturer knows the variation in diameter of the hole, and even if some manufacturing errors occur still the manufacturer has a value in which the diameter can vary and still the assembly will be possible and good enough. Hence, by using GD&T standards, manufacturing has become much easier for engineers and manufacturers.