Precision, accuracy, and efficiency are hallmarks of scientific research and laboratory workflows. Every year in the US alone 14 billion laboratory tests are administered, underscoring how dependent scientists are upon effective technology solutions in these settings.

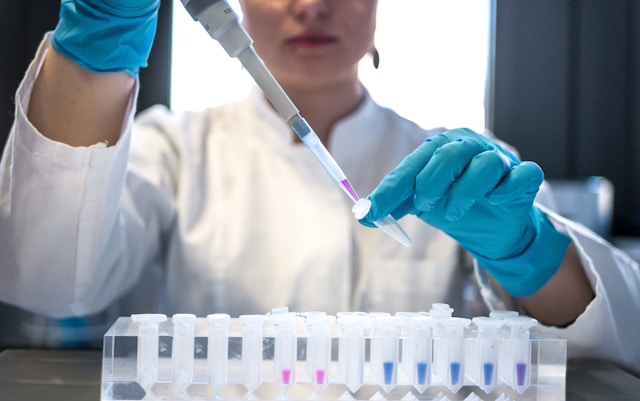

Liquid handling is one of the key intersections among these factors, where even minor errors can have major ramifications for experimental outcomes. Automated pipetting and liquid handling equipment have dramatically transformed laboratory processes by increasing throughput while decreasing human error rates.

This article covers considerations and strategies to optimize laboratory efficiency using automated pipetting systems and liquid handling equipment.

Understanding Automated Pipetting Systems

Modern automated pipetting systems have been carefully engineered to perform liquid handling tasks with extreme precision and unwavering consistency. These advanced systems usually consist of sophisticated robotic arms equipped with precision pipettes, enabling the aspirating or dispensing of liquids following strict protocols set out for their usage.

Understanding these systems’ intricacies is vital to unlocking their full potential and increasing laboratory productivity. Key considerations when choosing an automated pipetting system such as pipette accuracy, versatile volume range capabilities, and compatibility with an assortment of liquid types must all be assessed carefully during the selection process.

Integration with Laboratory Information Management Systems (LIMS)

Efficient data management is crucial to optimizing laboratory workflows. Integrating automated pipetting systems with laboratory information management systems guarantees seamless communication and comprehensive tracking. This integration connects pipetting protocols directly to sample information, eliminating manual data entry errors and improving traceability throughout experiments.

Real-time monitoring of pipetting tasks becomes possible for proactive adjustments that ensure optimal conditions. Combining automated pipetting with LIMS facilitates data analysis and reporting to advance scientific discoveries more rapidly, increasing operational efficiency, precision, credibility, and research outcomes, thereby marking an advancement of laboratory practices.

Calibration and Maintenance Protocols

Automated pipetting systems need regular calibration and maintenance protocols in place in order to function optimally and ensure accurate dispensation, while preventative tasks like cleaning or part replacement help reduce downtime as well as costly repairs.

Robust calibration and maintenance protocols are vital in prolonging the lifespan and reliability of automated pipetting equipment. Calibration involves fine-tuning pipetting parameters so they align with standards, while routine cleaning eliminates contaminants that could compromise operations. Timely part replacement reduces risks of malfunction and downtime, and prioritizing these protocols ensures consistent performance, minimized errors, and improved research quality.

Considerations for Liquid Handling Workflow

An effective liquid handling workflow necessitates meticulous consideration of various factors, including sample types, volume ranges, and experimental protocols. Automated pipetting systems offer great versatility, accommodating liquids of various viscosities, densities, and solvents with precision.

However, achieving seamless compatibility with specific applications requires extensive planning. Workflow optimization strategies involve preprogramming pipetting protocols tailored specifically for experimental needs, optimizing tip usage for efficiency, and integrating stringent quality control measures. These measures are essential in guaranteeing the accuracy and reproducibility of results, minimizing errors, and increasing overall laboratory productivity.

By aligning automated pipetting capabilities with optimized workflow strategies, researchers can streamline operations, accelerate experiments, and drive scientific advancement forward with greater precision and reliability.

Training and User Proficiency

While automated pipetting systems boast advanced capabilities, user proficiency has an enormous effect on their efficiency. Providing comprehensive training programs for laboratory personnel is key to ensuring they can operate and troubleshoot automated pipetting equipment efficiently. Ongoing support mechanisms, including user manuals and technical documentation, are essential in meeting any challenges that might arise during normal use.

Labs that invest in user training and robust support infrastructure can empower their personnel to harness the full potential of automated pipetting systems for enhanced operational efficiency and optimal experimental outcomes, creating an atmosphere of continuous improvement within their laboratory environment. This proactive approach fosters continuous innovation within its ranks.

Bottom Line

Automated pipetting and liquid handling equipment play an essential part in improving laboratory efficiency by decreasing manual labor and errors, and optimizing workflow automation. By understanding the capabilities of automated pipetting systems, integrating them with LIMS platforms, optimizing liquid handling workflows with standard protocols implemented, and offering comprehensive training to users as needed, laboratories can achieve higher throughput rates with improved data quality while being more cost-efficient at conducting their research activities. Ultimately this leads to higher throughput speeds for research efforts as a whole. By adopting these best practices automated pipetting remains at the heart of modern laboratory operations today.