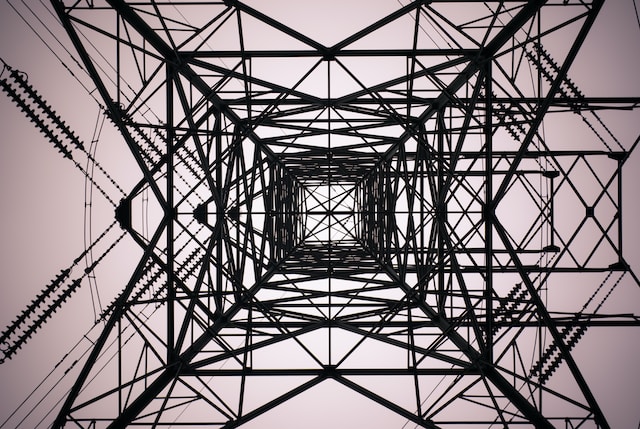

As a lineman, you play an important role in ensuring that power is safely and effectively transported to homes, businesses, and other structures. However, controlling electricity may be extremely dangerous, so it’s crucial that you follow the appropriate precautions to keep yourself protected. In this post, we’ll go over some of the most important electrical safety facts and lineman tools that every lineman should be aware of.

Overview of Electrical Safety

Before delving into the specifics of electrical safety for linemen, it’s necessary to understand what power safety comprises. Electrical safety refers to a collection of practices and precautions designed to keep people safe from electrical risks. Everything from correctly grounding electrical equipment to wearing the appropriate personal protective equipment (PPE) is covered.

Working with electricity is incredibly dangerous, and the consequences of an electrical hazard can be serious or even life-threatening. Electrical shocks can cause serious bodily harm or even death, and electrical fires can develop swiftly and result in substantial damage or wealth loss. As a result, it is critical that linemen take electrical safety seriously and follow best practices to reduce the likelihood of electrical risks.

Personal Protective Equipment (PPE)

Wearing the proper PPE is one of the most critical parts of electrical safety for linemen. PPE, which includes equipment such as hard hats, gloves, safety glasses, and insulated boots, is designed to protect you from electrical risks. It is critical to wear the appropriate PPE for the job at hand and to keep your PPE in good shape and well-maintained. Gloves, for example, should be checked before each use for holes or other signs of wear, and hard helmets should be changed if they become cracked or torn.

Electrical Hazards

There are a number of electrical hazards that linemen may encounter while on the job. These include:

- When a human comes into contact with a live electrical current, this results in electrocution. Electrocution can result in serious damage or even death, therefore it’s critical to take precautions to avoid coming into touch with live wires.

- Arc Flash: An arc flash is a form of electrical explosion that can occur while working on electrical equipment. This can result in significant burns or other injuries, so it’s critical to take precautions to avoid arc flashes.

- Electrical Fires: An electrical fire can start when faulty electrical equipment or wiring overheats. These fires can be difficult to extinguish and spread quickly, causing considerable damage.

To reduce the risk of these and other electrical risks, it is critical to adhere to established safety measures at all times. This includes recognizing potential hazards before starting work, de-energizing equipment before working on it, and wearing appropriate personal protective equipment (PPE).

Tools and Equipment

Linemen work with a variety of tools and equipment, including power tools, hand tools, and heavy equipment such as bucket trucks. When using equipment, it is critical to use suitable tool for the job and to follow proper safety practices. Tools, for example, should be inspected before use to ensure they are in excellent working order, and heavy equipment should only be operated by professionally trained and certified workers.

Working in Different Environments

Linemen may work in many different kinds of situations including underground, overhead, and in harsh weather. Each situation has its unique set of hazards and obstacles, so it’s critical to take the necessary safety precautions. For example, when working overhead, ensure that you are adequately secured to avoid falls, and when working below, ensure that the space is appropriately vented to avoid the buildup of harmful gasses.

Emergency Preparedness

Even with proper safety procedures in place, accidents can still happen. That’s why it’s important to be prepared for emergencies. This includes having an emergency response plan in place along with interacting effectively with team members. It is also critical to have suitable first aid supplies readily accessible and to understand how to deliver first aid in an emergency.

Training and Education

Finally, linemen need to value constant training and education. This can range from on-the-job instruction to formal schooling and certification. Continuous education and development may assist linemen stay current on the newest safety practices and technologies, allowing them to do their work more safely and efficiently.

Conclusion

Working as a lineman can be a great and exciting job, but safety must always come first. Linemen can assist in reducing the risk of accidents and injuries by following proper safety practices, wearing suitable PPE, and remaining up to speed with the latest training and information. Remember that your safety comes first, and taking the appropriate precautions to safeguard yourself and your team members will help ensure a long and prosperous career.

FAQs

- What types of PPE should a lineman wear?

- Linemen should wear personal protective equipment (PPE) such as hard hats, gloves, safety glasses, and insulated boots.

- What should a lineman do in case of an electrical accident?

- In case of an electrical accident, linemen should promptly de-energize equipment and ask for medical assistance if an electrical catastrophe occurs.

- Why is it important to use the right tools for the job?

- Using the right tools for the job can assist guarantee that the job is carried out effectively and reliably, as well as reduce the chance of serious injuries or accidents.

- What are some common electrical hazards that linemen may encounter?

- Linemen may be exposed to electrical risks such as electrocution, arc flashes, and electrical fires.

- How can linemen stay up to date with the latest safety practices and technologies?

- Linemen can stay updated on the latest safety procedures and technology by participating in ongoing training and education, attending industry conferences and events, and reading industry publications or journals.