Lubrication-free units for conveyor tables improve load-bearing capacity

igus has introduced new ball transfer units that allow lubrication-free and smooth transport with a dramatic increase in load-bearing capacity.

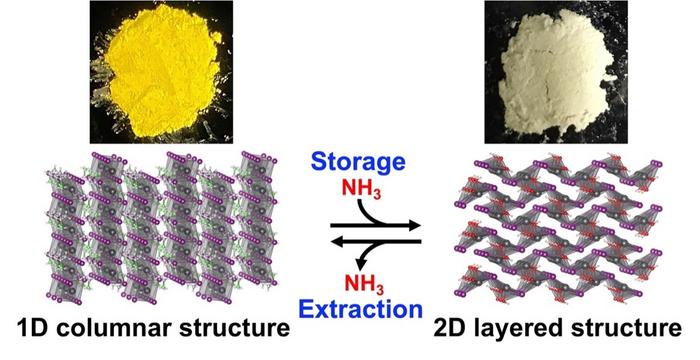

Ball tables are used if delicate or heavy goods are to be transported in different directions. The ball transfer units from igus are manufactured with the high performance plastic xirodur B180, which absorbs loads of up to 500 N. igus, which is based in Germany, runs its North American operations out of Providence, R.I.

The ball transfer units are lubrication and maintenance free. They also include stainless steel balls inside the roller to allow for smooth running.

Loads can be transferred quickly and easily

Ball tables are used wherever sensitive or heavy loads are transported from A to B, for items such as circuit boards, food, goods in airports, glass panes or goods in the sheet metal processing industry.

By using ball transfer units in the conveyor tables, loads can be transferred quickly and easily in any direction. The new ball transfer units from igus are made with the material xirodur B180, which ensures smooth transport even at high loads.

The units are dimensionally identical to metallic ball transfer units, but that is where the similarity ends. All igus units are lubrication-free and maintenance-free, ensuring no lubricants can adhere to the goods. By using a plastic ball, the use of new rollers is particularly suitable when sensitive goods are to be transported. Another distinguisher from metal is that the ball transfer units can be used in any installation position — horizontal, vertical or overhead — which now also extends the field of application to the furniture industry.

Five times more load-bearing capacity due to new design

The polymer ball transfer units also have a new housing interior, and can now take up to five times more load than before. The ball transfer units are currently available in three installation sizes and, depending on their size, withstand an axial load of 150 to 500 N.

Due to their material, they are very abrasion-resistant, have a long service life and have an electrically insulating effect. The rollers are mounted by simply pressing into the housing. igus also offers a clamping ring for extra security.

If customers require glass balls to be used inside the housing, the ball transfer units can be individually assembled upon request as a completely metal-free and non-magnetic solution.

About: igus® develops industry-leading energy chain® cable carriers, chainflex® continuous-flex cables, drylin® linear bearings and linear guides, iglide® plastic bushings, and igubal®spherical bearings. These seemingly unrelated products are linked together through a belief in making functionally advanced, yet affordable plastic components and assemblies. With plastic bearing experience since 1964, cable carrier experience since 1971 and continuous-flex cables since 1989, igus provides the right solution from over 100,000 products available from stock. No minimum order required. For more information, contact igus at 1-800-521-2747 or visit www.igus.com.