As a species, we’ve been making wine or other grape-based fermented drinks since 7,000 BCE, nearly 9,000 years ago. The process hasn’t changed much over the years — crush the grapes, introduce yeast to the mixture and allow it to ferment until it reaches the desired flavor and alcohol content. Recent technological innovations have changed the way we look at winemaking. How is technology changing the wine industry?

Irrigation Management

Climate change is threatening to rock the wine industry to its core. Droughts in some of the best wine vineyards in the world mean it’s up to the growers to ensure their grapes are getting enough water. Instead of watering all the time and potentially drowning the vines, vineyard owners can use drones to assess the state of their crop and determine the best times to water. These drones can even read the photosynthetic activity of each plant to evaluate their health.

Updated Processing Steps

Historically, much of the winemaking process was manual, but that’s not feasible anymore when vineyards have to create hundreds or thousands of bottles a year to keep up with demand. Compressed air has become an integral part of the winemaking process, assisting with everything from pressing grapes to bottling the finished product. Compressed air accounts for 68% of the energy consumption of large wineries and 36% in small ones. The significance of this advancement might not seem remarkable to you, but it enables even small, privately owned wineries to keep up with consumer demand.

Assessing Smoke Contamination

Even if the vineyard doesn’t burn, a nearby brush fire can contaminate an entire crop with smoke. These smoked grapes yield an unpleasant-tasting wine. Previously, the only way to determine a spoiled crop was to invest in expensive laboratory tests, but now drones can do all that work in a fraction of the time. Smoke-contaminated vines register at a different temperature than intact ones, so vineyard owners can preserve the rest of the crop by removing only the affected vines.

Yield and Quantity Predictions

Traditionally, the only way to figure out how much wine a crop would yield was to harvest and process it. Vineyard owners could make predictions, but with so many variables to consider — from the weather to the irrigation and fertilizer applied, pests and other concerns — it was nearly impossible to create an accurate prediction. Even planting sentinel species around the field to try and predict the yield would only provide 60 to 70% accuracy.

Now, vineyard owners don’t need to try and predict a given crop’s yield. Instead, they can input the data into a computer program, and the software will do all the work for them. With enough data, these machine learning systems can predict a crop’s yield with an accuracy of 80 to 90%.

When to Harvest

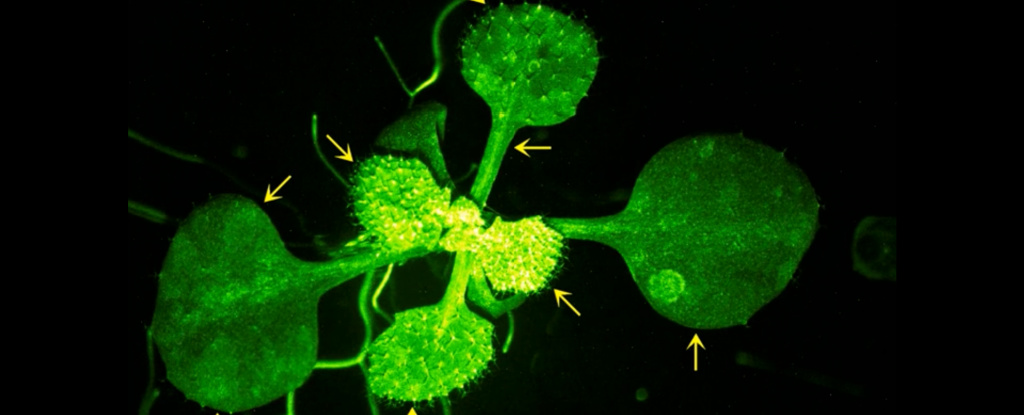

Vineyard owners have a tradition: When it comes close to harvest time, they go out into the field and taste the grapes to determine whether they’re ready. While this is both nostalgic and tasty, it’s not the most accurate way to determine when to harvest the crop. Recent research has shown the best way to assess whether a grape is ready to become wine is to look at the pattern of cell death within the fruit.

Doing this might not be as romantic as walking out and tasting the grapes, but it’s more effective. Monitoring the grapes with near-infrared light wavelengths allows vineyard owners to see when each fruit is ready for harvest to create the best-tasting wine.

Looking Forward

Climate change will alter both the way we make wine and the way we thrive on this planet. New technology will help the wine industry adapt to these changes, providing us with tasty libations for decades to come.

About the Author: Scott Huntington is a writer from Harrisburg, PA who covers all things tech and automotive. Check out his site offthethrottle.com or find him on Twitter @SMHuntington.