GGB, the expert in “extreme condition bearing solutions” introduces yet another highly specialized solution in the market called EP®15. This new product is a plastic line of bearings that are engineered for Sun.

GGB, the expert in “extreme condition bearing solutions” introduces yet another highly specialized solution in the market called EP®15. This new product is a plastic line of bearings that are engineered for Sun.

The new bearing line features excellent resistance to UV radiation, combined with a capacity for abrasion-free and low-friction operation. This makes the EP®15 suitable for a wide range of demanding, “under the Sun” applications. Moreover, its low mass yet sturdy structure makes it ideal for recreational applications where there’s little accommodation for torque.

As with all GGB products, the EP®15 line was developed with cost in mind, so it won’t break the bank. The same applies to safety and environmental compliance guidelines that were considered throughout its design and manufacturing.

Perfect Down to The Micrometer

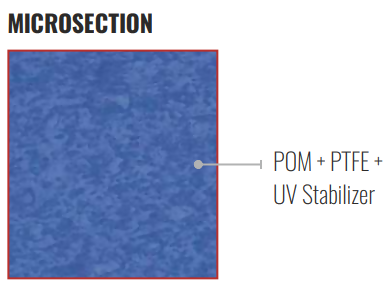

The EP®15 is made out of a polyoxymethylene polymer, featuring a UV stabilizer and polytetrafluoroethylene additives that give it it’s characteristic blue color. GGB has managed to formulate the composition of this new plastic line in a way that supports seamless operation even in low-lubrication scenarios.

While the EP®15 excels with oil, grease, and silicon lubrication, it can yield fair results with plan water, or even when it’s completely dry. The structure of EP®15 sports a very low dry coefficient of friction (0.09 – 0.15), so it won’t suffer from heat generation that can easily warp or distort other plastic solutions.

Ready for Repeated and Extensive Exposure to Sunlight

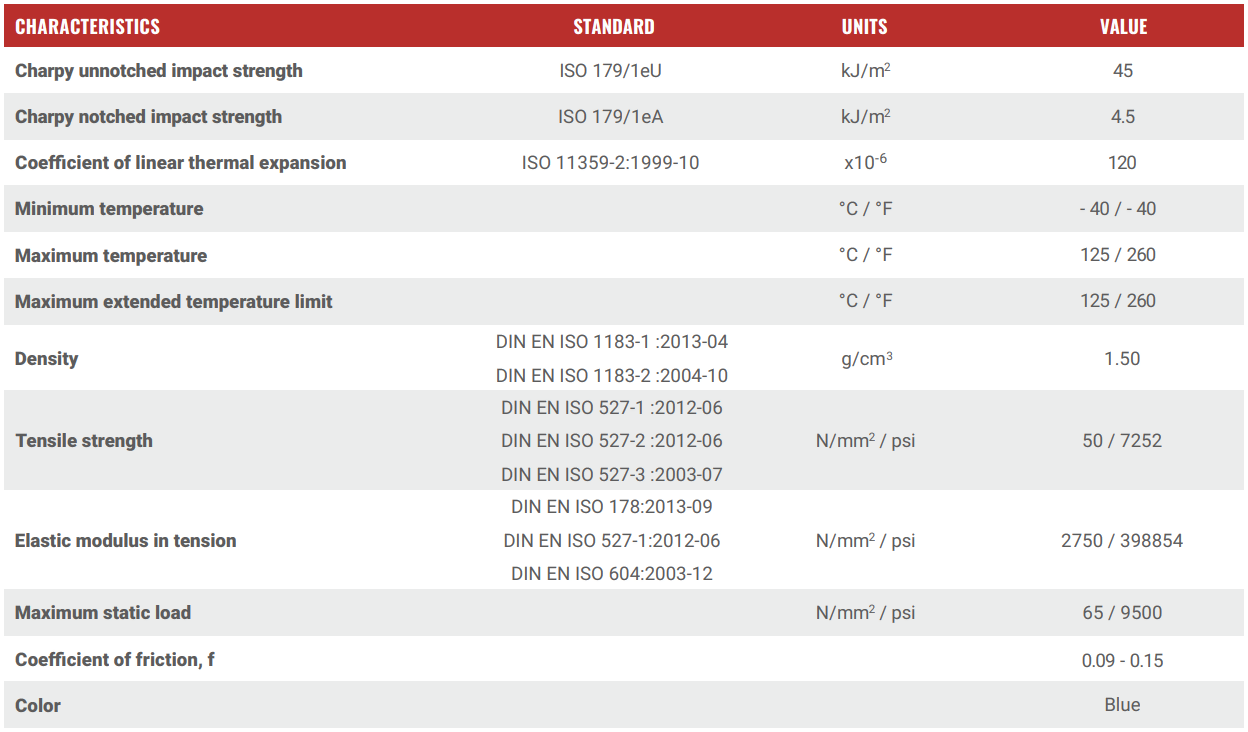

EP®15 can operate to temperatures of up to 125 degrees Celsius (260OF), and at a minimum temperature of minus 40OF. At a density of only 1.5 g/cm3, it features a tensile strength of 7252 psi (50 N/mm2), a maximum static load of 9500 psi (65 N/mm2), and a charpy unnotched impact strength of 45 KJ/m2.

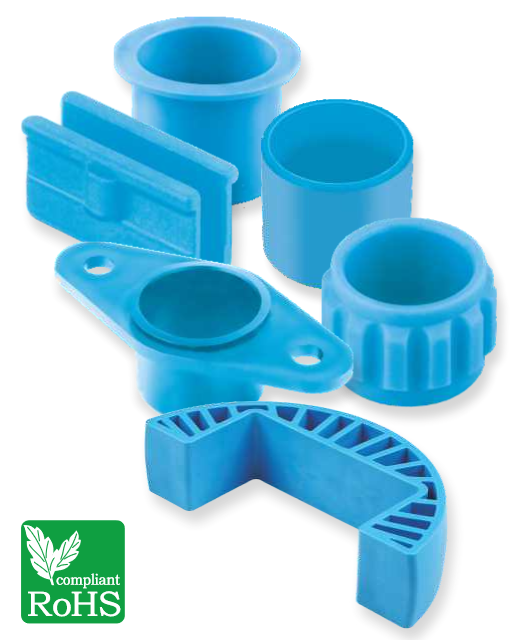

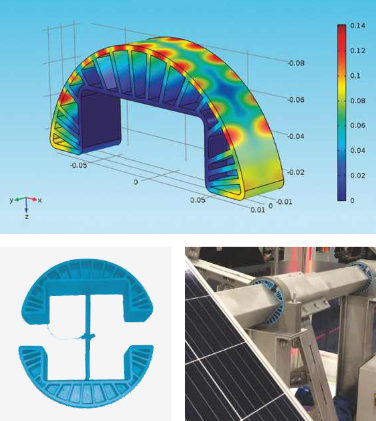

These characteristics make the new line suitable for a wide spectrum of applications, as EP®15 can safely take many shapes and sizes, fit anywhere, come with complex geometry, and reduce the overall weight and cost of a system.

Possible Applications

EP®15 is ideal for virtually any application that calls for UV resistance while at the same time having limited rotational speed and load requirements. From aerospace and automotive applications where the exposure to sunlight is continuous and unforgiving, to agricultural, construction and industrial applications, there are many potential cases were EP®15 would shine.

The most common however concern energy (photovoltaic and solar panels), and recreational applications (umbrella stands, watersports, etc.). EP®15 is also a great and environmentally-friendly choice for reusable packaging that could be exposed to the elements during the summer. Because of the versatility in the design, size, and the features that EP®15-based solutions can have, the possible applications are often only limited by the imagination of the engineer.

The GGB Expertise

Trusting GGB is to trust a renown global manufacturer and developer of advanced self-lubricating and pre-lubricated solutions. They possess the know-how and the expertise to move the developments in their field forward, introduce new products that conquer the market with impetus, and produce large numbers of pieces with incomparable repeatability and extremely low defect rates.

Operating eight manufacturing facilities in the U.S., Germany, France, Brazil, Slovakia, and China, GGB guarantees that you’ll get the volume that you ordered quicker than anyone else in the field, but without any compromises or discounts in the quality.

Low Cost, Compliance, Longevity

The EP®15 can work with minimal or no lubrication at all, and is compliant with the RoHS, WEEE, and EVL specifications. This means that no harm is made to the environment from lubricating grease leftovers, abraded plastics, and the need for additional power to move heavier parts. Moreover, EP®15 is an entirely maintenance-free solution, leaving the choice of lubrication in the discretion of the user.

This further reduces the impact and cost of using the product. Finally, GGB promises that EP®15 will be good for an extended service life, and while this can’t be determined with precision due to the variety that underpins each application, you should expect up to three-fold of the time period you’re getting from other “premium” solutions in the market.

Download the GGB EP®15 datasheet HERE.

For questions and assistance, contact a GGB engineer