In the fast-paced world of construction, agriculture, and manufacturing, heavy equipment and machinery play a crucial role in getting the job done efficiently. Reef group’s essential guide on moving heavy machinery emphasizes that while these powerful tools undoubtedly increase productivity, they also pose significant risks if not handled with care. Whether you are an experienced operator or a novice, prioritizing safety is paramount to prevent accidents and ensure a secure working environment. Let’s delve into some crucial safety tips to keep in mind when operating these powerful tools.

- Prioritize Training and Certification

Before operating any heavy machinery, it is imperative to undergo thorough training and obtain the necessary certifications. Familiarize yourself with the specific equipment you’ll be using, including its controls, functions, and safety features. Many accidents occur due to operator error or lack of understanding of the machinery’s capabilities. By investing time in training, you not only enhance your skills but also reduce the risk of accidents on the job site. Remember, safety starts with knowledge.

- Conduct Pre-Operation Inspections

Performing pre-operation inspections is a fundamental safety practice that should never be overlooked in the operation of heavy equipment. It serves as a proactive measure to identify and address potential issues or malfunctions before they escalate. Before starting any heavy machinery, operators should conduct a thorough inspection, paying attention to details such as loose bolts, leaks, worn-out tires, and any signs of damage. Additionally, it is crucial to ensure that all safety features, including brakes, lights, and alarms, are in proper working order. By incorporating regular maintenance and inspections into the routine, not only can unexpected breakdowns be prevented, but a safer working environment is also fostered, enhancing overall workplace safety.

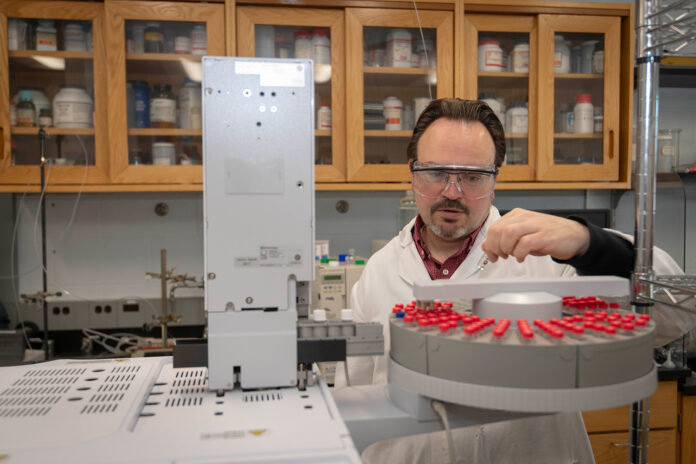

- Wear Appropriate Personal Protective Equipment (PPE)

Personal protective equipment is a critical line of defense against potential hazards in the workplace. When operating heavy machinery, wearing the right PPE can significantly reduce the risk of injuries. This may include a hard hat, safety goggles, gloves, steel-toed boots, and hearing protection. The type of PPE required may vary depending on the specific machinery and the nature of the job. Always adhere to the manufacturer’s recommendations and industry standards when selecting and using PPE.

- Be Mindful of Surroundings

One of the leading causes of accidents involving heavy equipment is inadequate awareness of the surroundings. Before operating machinery, survey the work area for potential hazards such as uneven terrain, overhead power lines, or other workers. Establish communication protocols with coworkers, especially when visibility is limited. Utilize spotters if needed, and always be aware of blind spots. Taking the time to assess the environment can prevent collisions and accidents, ensuring a safer working atmosphere.

- Follow Proper Loading and Unloading Procedures

Loading and unloading heavy equipment can be a delicate process, requiring precision and caution. Always follow the manufacturer’s guidelines and recommended procedures for securing loads. Ensure that the equipment is properly balanced and that the load does not exceed the machine’s capacity. Use the appropriate lifting accessories, such as slings or chains, and double-check the integrity of tie-downs. Mishandling loads during loading or unloading can lead to accidents and damage to the equipment.

- Keep Emergency Procedures in Mind

No matter how cautious you are, emergencies can still occur. It is crucial to be prepared for unexpected situations by familiarizing yourself with emergency procedures. Familiarize yourself with the whereabouts of emergency exits, fire extinguishers, and first aid kits. Establish communication channels for quick response in case of accidents or breakdowns. Regularly conduct emergency drills to ensure that all personnel are familiar with the procedures and can respond effectively to unforeseen events.

- Respect Weight and Height Limits

Every piece of heavy machinery has specified weight and height limits that should never be exceeded. Overloading equipment can compromise its stability and lead to catastrophic failures. Always consult the equipment’s manual or load capacity chart to determine its limitations. Additionally, be mindful of height restrictions, especially when operating near structures or power lines. Ignoring these limits can result in tip-overs, structural damage, or electrocution.

- Stay Alert and Avoid Distractions

Operating heavy machinery requires full attention and focus. Avoid distractions such as using mobile phones, eating, or engaging in conversations while operating equipment. Distracted operators are more prone to errors and are less likely to notice potential hazards in their surroundings. Stay alert, maintain situational awareness, and prioritize the task at hand. Creating a culture of attentiveness on the job site contributes to a safer working environment for everyone involved.

Final Thoughts

Safety should always be the top priority when working with heavy equipment and machinery. By following these essential safety tips, operators can minimize the risk of accidents, injuries, and damage to equipment. Remember to prioritize training, conduct thorough inspections, wear appropriate PPE, be mindful of your surroundings, and always follow proper procedures.