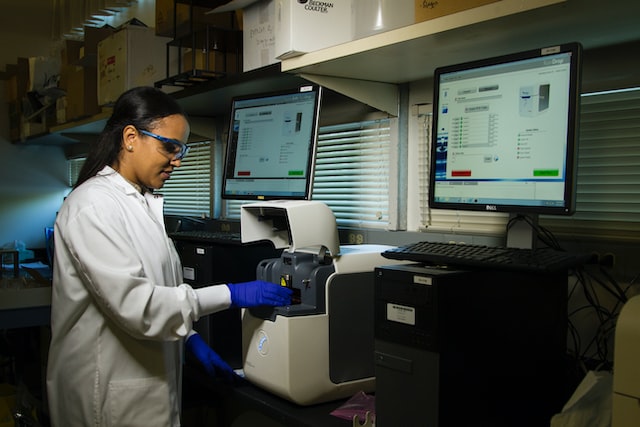

Inlabtec AG reports upon the positive results from a 30-month use, by SGS Fresenius GmbH (Germany), of the Inlabtec Serial Diluter for food quality and safety testing.

SGS is the world’s leading inspection, verification, testing and certification company and recognized as the global benchmark for quality and integrity. With more than 90,000 employees, SGS operates a network of more than 2000 offices and laboratories around the world. SGS INSTITUT FRESENIUS GmbH as part of the SGS Group Germany is one of the most important German providers of laboratory analytics for the safety and quality of food, beverages and consumer products with an excellent reputation among producers, consumers and trade.

The Inlabtec Serial Diluter has been successfully used by lab staff at SGS Fresenius since the beginning of 2015 eliminating the traditionally time-consuming, laborious tasks of test tube filling, sample cap handling and vortexing during dilutions.

To make sampling out of standard homogenizer bags (stomacher bags) easier, the laboratory team decided after a three-week intensive test phase to change to the recently introduced Inlabtec Serial Diluter SA for pipette straws.

The entire SGS laboratory team was quickly convinced by the improved sample handling and enhanced productivity when working with straw pipette tips. In addition, using the Inlabtec Serial Diluter to sample out of standard homogenizer bags has made the whole process even easier and faster.

Despite initial skepticism from some lab staff, the integration of the Inlabtec Serial Diluter into the existing workflow was quick and easy since no process changes or special training was required. SGS have reported considerable time savings using the Inlabtec Serial Diluter and cost savings related to eliminating the need to clean and then store dilution test tubes in a refrigerator. The Inlabtec system has provided reliable sterile operation as has been expected from the instrument’s design.