When it comes to heavy equipment, hydraulic cylinders play a pivotal role in ensuring smooth operations. These powerful components are responsible for lifting, pushing, and pulling, making them critical for heavy machinery’s functionality. However, like any other mechanical part, hydraulic cylinders require regular maintenance to keep them in optimal working condition. In this article, we’ll delve into the importance of regular maintenance in heavy equipment hydraulic cylinder repair. We will explore how it can save you time, money, and headaches in the long run.

The Vital Role of Hydraulic Cylinders in Heavy Equipment

Hydraulic cylinders: The powerhouse of heavy equipment

Hydraulic cylinders are the unsung heroes of heavy equipment, providing the muscle needed to do the job. Whether it’s a construction crane, an excavator, or a bulldozer, hydraulic cylinders are what make these machines move mountains, literally. They convert hydraulic pressure into mechanical force, driving the machinery’s essential functions.

The high-stress environment

In the world of heavy equipment, these cylinders work under extreme conditions. They endure heavy loads, rugged terrain, and exposure to harsh elements. Such demanding environments can take a toll on their performance over time.

Why Maintenance Matters

Preventive vs. Reactive Maintenance

In the world of heavy equipment maintenance, there are two primary approaches: preventive and reactive. Reactive maintenance involves fixing a hydraulic cylinder only when it fails or exhibits noticeable issues. On the other hand, preventive maintenance involves regularly scheduled inspections and repairs, aiming to catch problems before they become critical.

Cost-Efficiency

One of the most compelling reasons to embrace regular maintenance is cost efficiency. While it may seem counterintuitive to spend money on something that’s not broken, it’s essential to view maintenance as an investment. Regular checks and small repairs are far more budget-friendly than major overhauls or replacements necessitated by neglect.

Downtime Reduction

Heavy equipment downtime is the bane of productivity and profitability. When a hydraulic cylinder fails unexpectedly, it can bring an entire project to a grinding halt. Regular maintenance helps avoid such unwelcome surprises, minimizing downtime and keeping your projects on schedule.

The Nuts and Bolts of Maintenance

Fluid Analysis

One crucial aspect of maintenance is monitoring the hydraulic fluid. Contaminated or deteriorated fluid can lead to cylinder damage. Regular fluid analysis can pinpoint issues early on and prevent costly repairs down the line.

Rod Rechroming

When it comes to hydraulic cylinder repair, rod rechroming is a game-changer. The hydraulic cylinder rod rechroming process involves restoring the cylinder’s rod to its original state by reapplying a chrome layer. It not only extends the rod’s lifespan but also enhances its performance, reducing wear and tear.

Choosing the Right Repair Shops

Finding the right hydraulic repair shop is paramount. Look for experienced professionals who specialize in heavy equipment hydraulic cylinder repair. If you’re in Chicago, search for “hydraulic cylinder repair Chicago” to find local experts who can address your specific needs.

The Importance of Hydraulic Cylinder Inspection

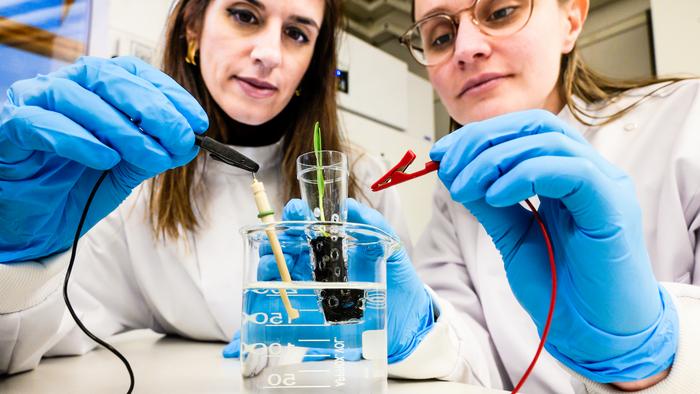

Regular inspection is the cornerstone of effective maintenance. It’s during these inspections that technicians can catch potential issues before they escalate into major problems. During a comprehensive inspection, experts examine every aspect of the hydraulic cylinder, from the rod to the seals and the hydraulic fluid. They look for signs of wear, corrosion, leaks, and any other anomalies that might compromise the cylinder’s performance.

Inspectors also pay close attention to the cylinder’s alignment and structural integrity. Misalignments can cause uneven wear and decreased efficiency, leading to premature failure. By detecting and correcting these issues early on, you can extend the life of your hydraulic cylinders and ensure they operate at peak efficiency.

In addition to visual inspections, technicians may also employ advanced diagnostic tools and testing procedures to assess the cylinder’s condition more accurately. This proactive approach not only prevents costly breakdowns but also contributes to overall safety on the job site. So, whether you’re operating heavy equipment in construction, agriculture, mining, or any other industry, scheduling regular hydraulic cylinder inspections should be a non-negotiable part of your maintenance routine. It’s a small investment in time and resources that pays off in terms of equipment reliability and job site productivity.

The Role of Hydraulic Repair Shops

Expertise and Specialization

Hydraulic repair shops are your partners in keeping heavy equipment running smoothly. These specialized workshops have the knowledge and tools needed to diagnose and repair hydraulic cylinder issues effectively. They understand the unique demands of heavy machinery and can provide tailored solutions.

Regular Inspection and Servicing

Hydraulic repair shops can conduct regular inspections and servicing of your hydraulic cylinders. They follow manufacturer-recommended guidelines and industry best practices to ensure every component is in top condition. This proactive approach prevents unexpected breakdowns and costly repairs.

Emergency Repairs

In some cases, despite diligent maintenance, hydraulic cylinders can still fail. When that happens, hydraulic repair shops can provide emergency repair services. They have the expertise to quickly diagnose the issue and perform necessary repairs to get your equipment back on track.

Conclusion

In the world of heavy equipment, hydraulic cylinders are the unsung heroes that keep the wheels of industry turning. Regular maintenance is the key to ensuring these vital components operate smoothly and efficiently. It’s a cost-effective strategy that reduces downtime, prevents major breakdowns, and extends the life of your equipment. So, don’t wait until your hydraulic cylinders give out; invest in regular maintenance and keep your heavy machinery running like a well-oiled machine.

Incorporating regular maintenance into your heavy equipment management strategy is not an option; it’s a necessity. It’s the difference between a smoothly running operation and costly downtime. So, remember: regular maintenance today means fewer repair bills and more productivity tomorrow. Whether you’re in Chicago or anywhere else in the world, prioritize the health of your hydraulic cylinders for the longevity and efficiency of your heavy equipment.