Precision engineering stands as a pillar of modern manufacturing and design, enabling the creation of highly specialized, high-quality products across various industries. This discipline involves the meticulous development and execution of designs to extremely tight tolerances, ensuring consistency, reliability, and optimal performance. In this article,

Ready to turn potential into reality? Explore how Precision Engineering can elevate your projects. Whether optimizing the performance of existing products or breaking ground on revolutionary new designs, embracing these advanced techniques is your next step. Let’s unlock the potential together and set new standards in your industry.

What is Precision Engineering?

Precision engineering is a subfield of engineering that focuses on designing machines, fixtures, and other structures that have exceptionally low tolerances, are repeatable and are stable over time. This discipline involves both the ability to design these components and the capability to produce them with high precision, which often requires advanced equipment and techniques. The overarching goal is to achieve the greatest level of accuracy and consistency in engineering tasks.

The Principles of Precision Engineering

The concept of tolerance is central to precision engineering. It refers to the permissible limits within which a physical dimension can vary. Precision, on the other hand, relates to a system’s repeatability and the minimal variance during its replication process. These two aspects are crucial for achieving high-quality products with consistent performance.

Materials and Manufacturing Techniques for Precision Engineering

The Precision Engineering strategic selection of Materials and Manufacturing Techniques is fundamental. As we delve deeper into the capabilities required to meet stringent specifications, materials such as advanced alloys, engineered polymers, and bespoke composites stand out. They are not merely chosen for their durability or strength; their selection is crucial for ensuring the desired performance under specific operating conditions.

Equally critical are the Manufacturing Techniques that bring these materials to life. Techniques such as custom CNC machining offer unmatched precision, while additive manufacturing pushes the boundaries of design complexity, enabling the creation of components with geometries that traditional methods could never achieve. Through these sophisticated techniques, engineers can ensure that each component not only fits perfectly but also performs optimally in its intended environment, exemplifying the essence of Precision Engineering.

The Role of Precision Engineering in Various Industries

Aerospace

In the aerospace industry, precision engineering is indispensable, Components such as turbine blades, structural panels, and instrumentation require exact specifications for safe and efficient operation. The high-performance demands of aerospace components mean that even the smallest error can have significant repercussions.

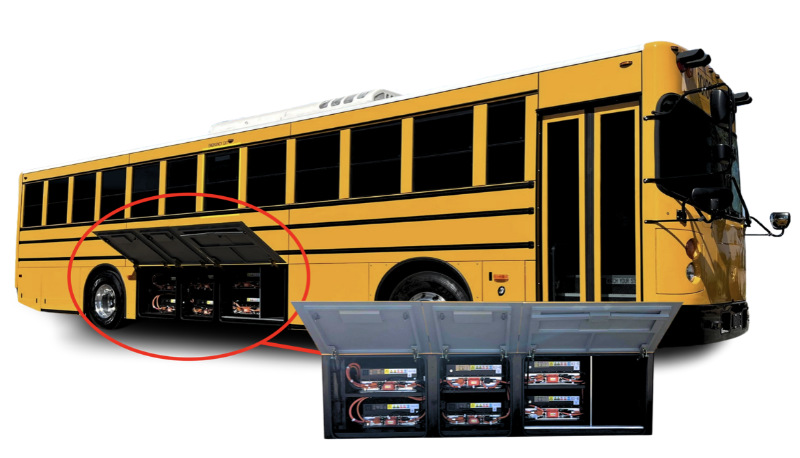

Automotive

The automotive sector relies on precision engineering to ensure the safety, performance, and durability of vehicles. From the engine block to the suspension systems, precision-crafted parts help in enhancing fuel efficiency and reducing emissions, while also providing the resilience needed to withstand the rigors of daily use.

Medical Devices

Precision is paramount in the medical device industry due to the critical nature of its applications. Instruments like surgical tools, implants, and diagnostic equipment must adhere to exacting standards to ensure patient safety and the effectiveness of medical procedures.

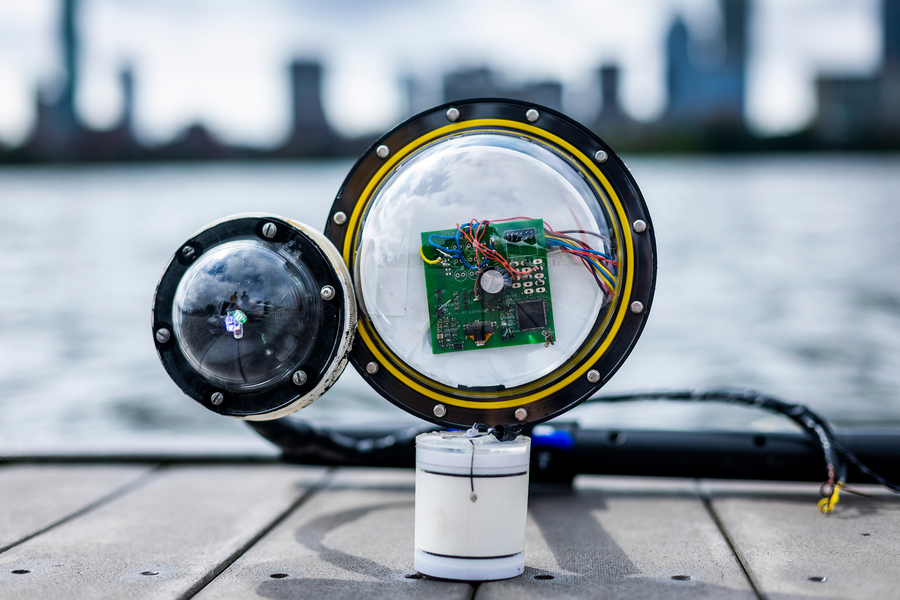

Electronics

Precision engineering enables the miniaturization and integration of components. Semiconductor chips, PCBs, and connectors must all be produced with precise tolerances to ensure functionality and reliability in increasingly compact devices.

Robotics

Robotics integrates precision engineering to create systems that can perform complex tasks with high accuracy and repeatability. From industrial robots that assemble cars to robotic arms used in surgery, each component must be precisely engineered to function seamlessly within its operational parameters.

The Advantages of Precision Engineering

Precision Engineering and Quality Assurance

Precision engineering directly contributes to the quality assurance of products. By adhering to stringent standards, manufacturers can minimize the occurrence of defects and ensure that each product performs as expected.

Customization and Flexibility

One of the significant advantages of precision engineering is its ability to tailor products to specific needs. This flexibility allows for innovation and customization in design, which is especially beneficial in industries requiring unique solutions.

Efficiency and Cost-Effectiveness

Precision engineering might require significant initial investment in terms of equipment and design, which ultimately leads to greater efficiency and cost-effectiveness. Reduced waste, lower rework rates, and improved product lifespan all contribute to a better return on investment over time.

Conclusion

Precision engineering is more than just an approach to manufacturing; it is a fundamental enabler of innovation and excellence in a multitude of fields. By understanding and applying the principles of precision engineering, industries can achieve not only higher standards of quality and efficiency but also push the boundaries of what is technically feasible. As technology advances, the role of precision engineering will undoubtedly become even more crucial, unlocking potential across new and evolving sectors.