Transforming Energy Production with Innovative 3D Printing Technology

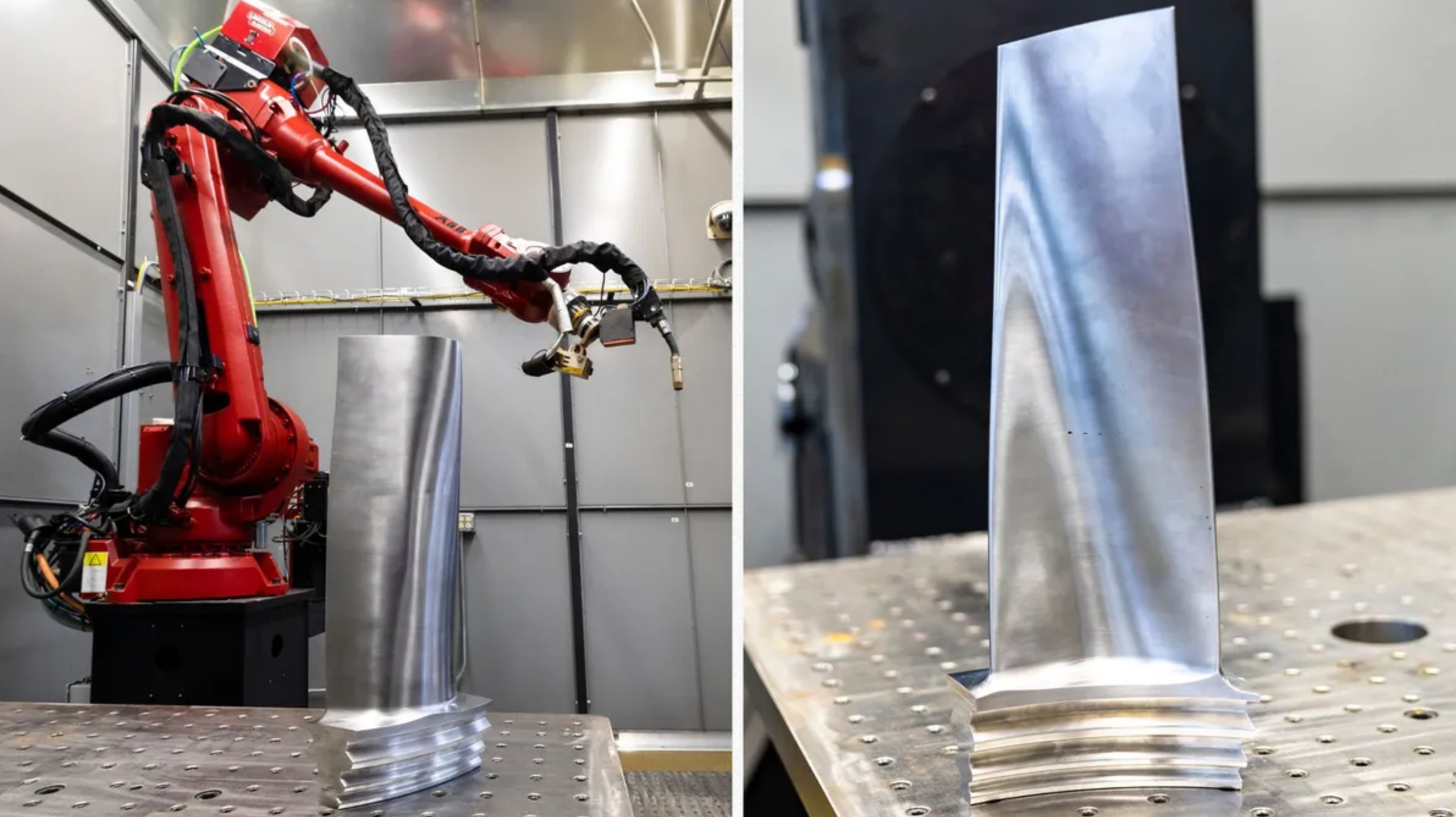

Researchers at the Department of Energy’s Oak Ridge National Laboratory (ORNL) have achieved a groundbreaking milestone by successfully 3D-printing large rotating steam turbine blades designed for power plants. This achievement, in collaboration with Siemens Technology, signifies a significant advancement in wire arc additive manufacturing.

The breakthrough highlights the technology’s potential to produce critical components weighing over 25 pounds (~11 kilograms), replacing traditional casting and forging processes that were often outsourced internationally. Wire arc additive manufacturing utilizes an electric arc, controlled by a robotic arm, to melt metal wire and systematically construct thin metal layers. These layers form intricate shapes that are later machined to meet final design specifications.

How 3D Printing is Reshaping Turbine Manufacturing

Lead researcher Michael Kirka at ORNL emphasized the urgency of their innovation, addressing the challenges in obtaining low-volume castings and forgings exceeding 100 or 200 pounds domestically. The collaboration with Siemens Technology aims to tackle issues related to the international movement of critical supplies. Siemens initially focused on wire arc research in 2019, primarily for component repair. However, the project’s scope expanded during the COVID-19 pandemic, with the extended wait time for new cast steam turbine blades becoming more pronounced.

As a response, the project expanded to include 3D printing for all replacement parts. Scanning during the build process reduced production time, allowing the creation of a large steam turbine blade in just 12 hours.

Machining allows for a fully finished blade in just two weeks, a substantial improvement compared to the traditional two-year timeline. The wire arc setup at ORNL demonstrated the potential to produce an entire blade in one build, showcasing increased efficiency.

This pioneering project illustrates the transformative potential of wire arc 3D printing for large rotating components in energy production.