Open source protection gear for workers, 3D printed by WASP. Italy calls and WASP gives innovations.

In compliance with the rules imposed by the Italian government for the health of workers and the fight against Covid-19. WASP has undergone a process of change converting its development ability in order to counteract the diffusion of COVID-19.

All the ongoing projects from its R&D department have only been temporarily set aside and ad hoc tools have been studied and designed, now we are able to present the first concrete results.

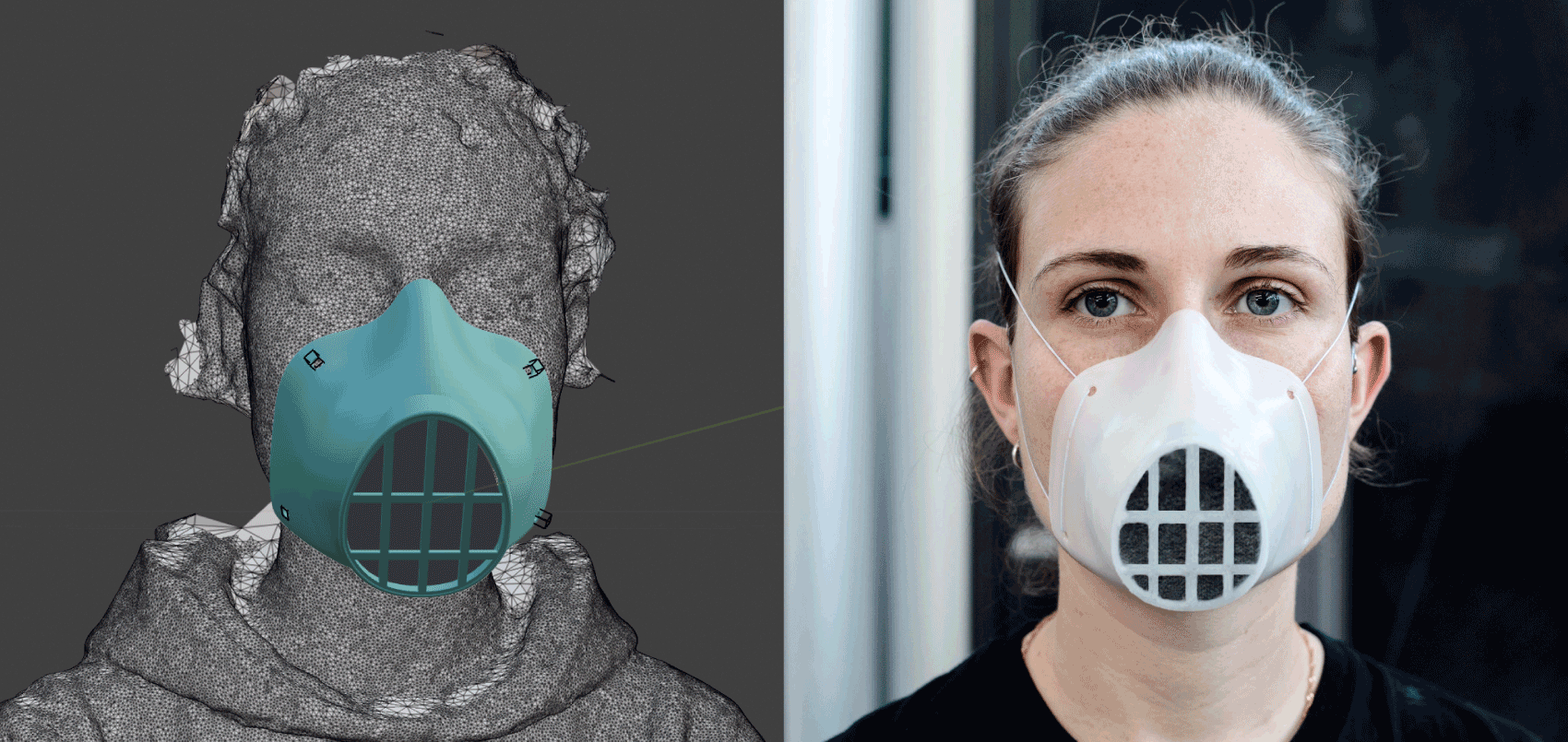

Mask with replaceable filter “MY FACE MASK”

|

|

WASP has developed a process that starts from 3D scanning the subject’s face, making a custom mask for every wearer. The material used is PCL (Polycaprolactone). An implantable biomaterial, that can, therefore, be used for direct skin contact. All the masks were printed using Delta WASP 4070 IND. 4.0.

Our goal was to make the mask perfectly ergonomic, following the facial features as a second skin, a result that we obtained Blender CAD-modelling software. “MY FACE MASK” can be easily sanitized and reused many times, as the central part features a replaceable filter. It only takes about 4 hours to customize a perfectly fit face mask, thus reducing skin irritation and long-use related issues.

WASP released the project in open source. On the website you can find all the instructions and the .stl files ready to be downloaded. WASP has decided to use photogrammetry to obtain a 3D scan of the wearer face since it’s the easiest method and can be performed using any smartphone camera. It can also be used if a standard 3D scanner if available.

Find the instructions clicking on the link below:

Micro-droplets protection helmet with ventilation and filter “MY SPACE”

Being able to get closer without the fear of being infected is one of the most urgent needs of the present moment.

A climate-controlled space, ventilated and safe from any virus. A positive air flow protection helmet. This is “MY SPACE”.

It is made of light transparent plastic material, it’s easy to wear and creates a safe personal space. Nose, mouth, eyes, ears, everything is contained in a slightly pressurized casing where you can feel a sense of protection, without the limitation of the respiratory capacity caused by the masks. Fresh and clean air comes from the top, while near the ears small holes allow hearing. The holes can be closed if necessary but a constant flow of air coming out from them ensures that nothing from the outside can get inside.

A 12V battery allows the fan to work for several hours. At the moment there are 5 “ready to use” helmets. These are non-certified devices that WASP will internally test to evaluate strengths and weaknesses and give them registered to those who work on the front line.

Also in this case the instructions for “MY SPACE” are available on our website: https://www.3dwasp.com/en/protection-helmet-with-ventilation/

It took only three days of work to go from the idea to the production of the masks and helmets for internal use. Of course our work doesn’t stop there.

Research continues and WASP places itself at the service of research centers, universities, public and private bodies, to share knowledge and experience. Together we will win.