Jim Stevens has 15 patents related to asphalt (aka bitumen) chemistry and physical properties under the name Green PAHs or Polynuclear Aromatic Hydrocarbon Suppressant. Stevens is a “rheologist,” studying the flow of matter in liquid state, as soft solids or as solids.

Stevens, now semi-retired, worked in the chemical industry for nearly four decades: six months in the field at chemical plants and six months in a chemical research lab each year. Stevens is now turning a lifetime of experience and knowledge into new technology that promises to significantly impact the rate and amount of CO2 emissions in the United States and beyond.

What is Asphalt?

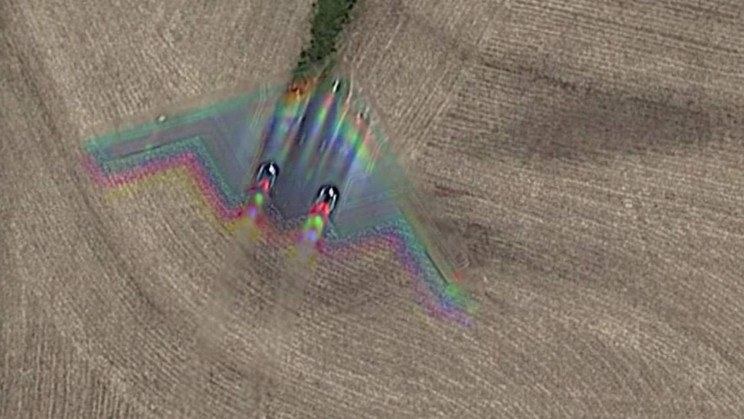

Asphalt is one of the by-products of fossil fuel refining. Asphalt is the dark bituminous pitch mixed with sand or gravel and used as surface on roads, flooring, roofing and more. The following image shows that over 100 MT of bitumen is used each year worldwide.

Asphalt Markets

According to Stevens, each year, Hot Mixed Asphalt (HMA), hot mix paving materials, hot asphalt pavement recycling products, hot mix plants, hot mopped asphalt roofing material and products using hot asphalt/bitumen in finished products emit smoke and fumes containing benzene, toluene, ethylbenzene, m & p xylene, 0-xylene and other pollutants, carcinogens and greenhouse gases (GHCs).

The United States produces 500,000,000 tons of hot mix asphalt annually. The carbon and carcinogen emissions created in maintaining our highways and byways produces in excess of 30 million tons of CO2 each year.

The Invention

Stevens’ invention is an additive that, when mixed with asphalt/bitumen, combines short chain molecules and long chain molecules thereby increasing the vapor point of short chain molecules from 300° to 500° and keeping harmful emissions out of the air.

In a “Headspace Analysis” carried out by an independent lab, Stevens’ technology reduces the following analytes. Note that this percent of reduction was achieved using only 2% of the additive and tested at 450°. Increasing the usage level will increase the percent of PAHs reduction.

- Acenaphthene – 41.45 % reduction

- Flourene – 87.48% reduction

- Phenanthrene – 89.81% reduction

- Anthracene – 86.72% reduction

- Fluoranthere – 78.57% reduction

- Pyrene – 75.83% reduction

The Case of California Cap & Trade

In the highly competitive industries that make and use asphalt prospects for Stevens’ invention, things are complicated by the fact that manufacturers balk at any incremental cost whatever the reason for it. However, in California, a CO2 Cap & Trade system has been set up where emitters of carbon can receive carbon credits for eco-friendly asphalt. According to Stevens, California’s 37 hot mix plants will not use the product and he believes legislative incentives are needed to see that manufacturers carry the added cost in the name of air quality, environment and climate change.

Health Implications

The US Centers for Disease Control (CDC) published a report, “Exposure to ashalt fumes CDC,” detailing the health altering and even deadly effect of asphalt fumes on workers involved in the paving, roofing and manufacturing industries.

Jim Stevens can be reached via email. Just click on the following link:

Send Mail