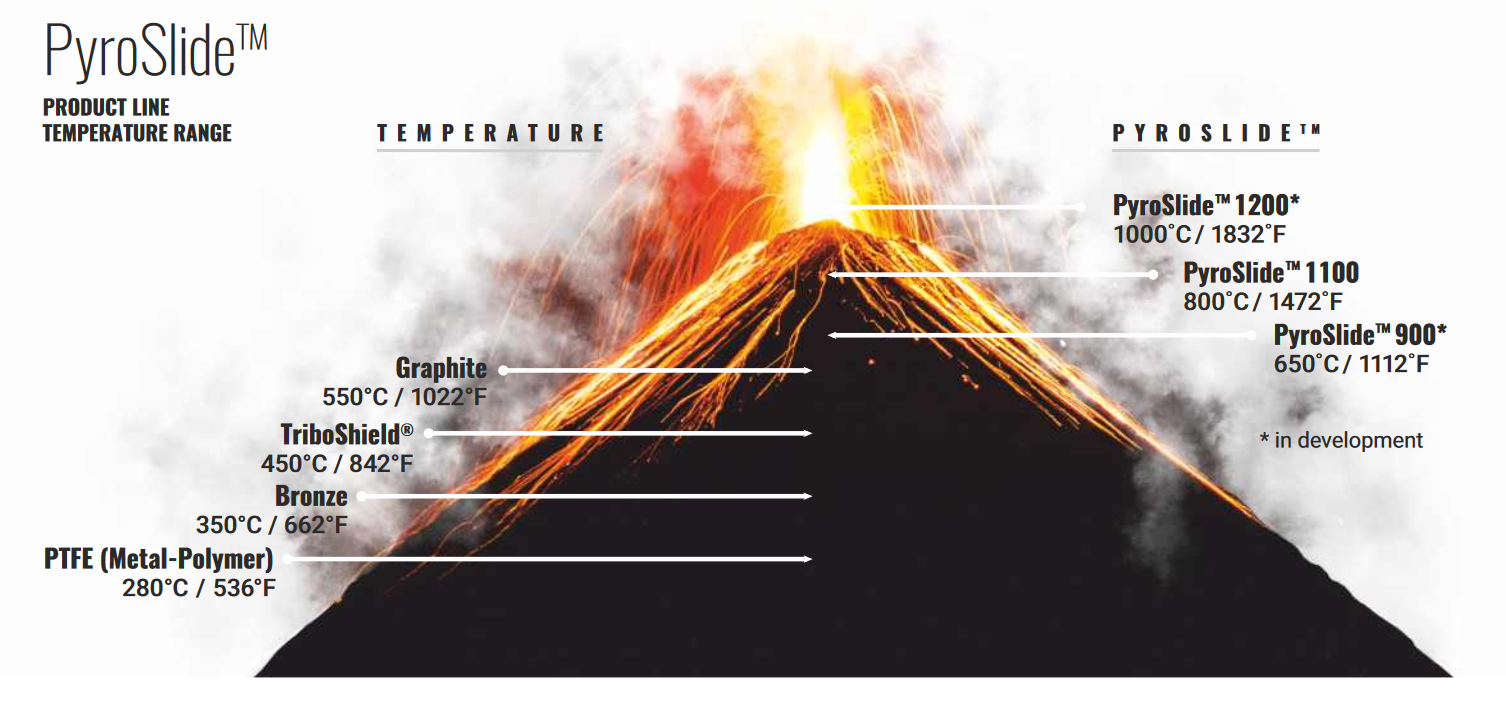

GGB, the experts in extreme condition bearing solutions has recently introduced a new high-temperature powder metal bearing series called the PyroSlide™.

Featuring Excellent Characteristics That Include:

Featuring Excellent Characteristics That Include:

- High-temperature resistance

- Corrosion resistance

- High load capacity

- High wear resistance

- Low-friction properties

- Self-lubricating

- Maintenance-free

How can a bearing combine all of these beneficial characteristics and stay affordable?

A Micro-Structural Advantage

GGB based the success of PyroSlide™ on the design and manufacturing of its metallic matrix, creating one that sports unprecedented homogeneity and is free of defects that can quickly lead to hardware failures when deployed at high-temperature conditions.

Inside the metal matrix, GGB engineers embedded and equally distributed a solid lubricant. The self-lubrication film is automatically formed on PyroSlide™ bearings during operation, requiring no additional lubrication or maintenance whatsoever.

Ready for Extreme Applications

The new series of GGB’s tribological solutions for high temperatures consists of PyroSlide™ 900, 1100, and 1200.

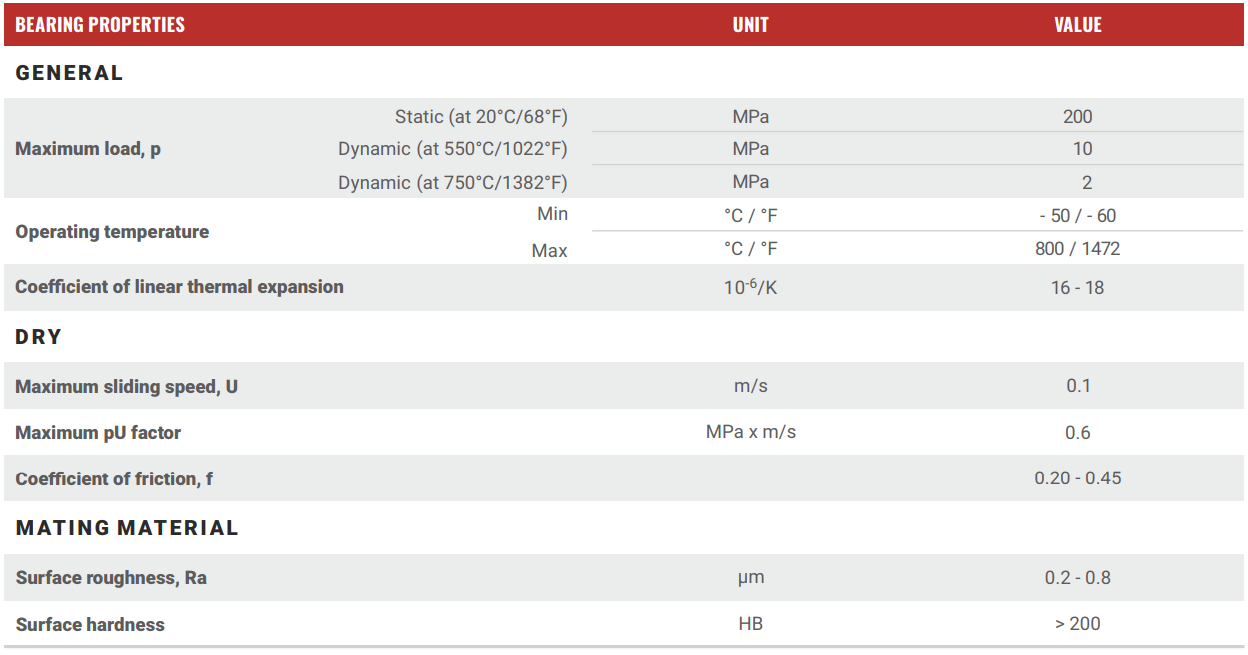

The PyroSlide™ 1100 sits in the middle of the potential practical scope, covering maybe the widest range of engineering applications. It’s able to run unproblematically from -50 OC and up to 800 OC (-60 OF to 1472 OF), has a very small coefficient of linear thermal expansion so it remains suitable for high-precision applications, and allows a maximum static load of 200 MPa at 20 OC, or a maximum dynamic load of 10 MPa at 550 OC, and 2 MPa at 750 OC.

The powder metal sintered alloy comes with a Brinell hardness of 200, so it doesn’t have special surface pairing requirements (annealed stainless steel would be suitable), making its deployment even more cost-efficient. Other solutions of this type require hardened tool steel or exotic synthetic super-hard materials that cost way too much.

Combining the above properties makes PyroSlide™ suitable for the following applications:

• Aircraft turboprop and turbofan engines

• Aerospace-grade engine guide vanes

• Aircraft engine pneumatic-bleed valves

• Automotive EGR (Exhaust Gas Recirculation) valves

• Exhaust throttle valves

• Exhaust heat recovery systems

• Exhaust breaks

• Wastegate valves

• Car engine turbo units

• Industrial or domestic ovens and furnaces

• Exhaust and smoke flaps

• Industrial valves used in high-temperature points and corrosive environments

• Natural gas and petrochemical valves

• Industrial gas and steam turbines

The GGB Bearing Expertise

While GGB is offering its PyroSlide™ bearing in various cylindrical shapes, there are also various types and sizes of washers, flanged bearings, and plain designs that are readily available. If nothing fits your specific needs, the French manufacturer can also accept custom orders and even cover high volume production demands. The company has extensive experience in the development and procurement of solutions for the aforementioned sectors, as well as for the metal production industry where high temperatures are to be found across the production line. A characteristic and indicative example of GGB’s expertise and the reliability of their self-lubricated bearings is that one of them is still spinning inside the drill that NASA’s Curiosity rover on Mars is using to acquire rock samples.

Compliance, Safety, and Longevity

Besides the expected longevity of PyroSlide™ 1100, the lack of any need for lubrication or maintenance, and the low friction that reduces the noise and vibrations that would be passed to adjacent parts, there is one more element that makes it a preferred investment, and that is its minimal environmental impact. From how the raw material suppliers of GGB mine the metals to how the PyroSlide™ bearings are manufactured, every step of the way is optimized to consume less energy and emit fewer pollutants.

On the same page, the PyroSlide™ bearing is using no grease and no lead, so it is compliant with the RoHS directive for electrical and electronic equipment, as well as most of the national and international environmental regulations.

View the PyroSlide™1100 Data Sheet: HERE

For questions and assistance, contact a GGB engineer