Every single business that exists relies on some form of supply chain. From the biggest supermarkets and businesses to the smallest mom-and-pop stores, there’s no escaping how vital a steady supply chain is.

Therefore, it’s unsurprising that 57% of companies believe proficient supply chain management provides a competitive edge. Businesses and companies that work toward cutting down on supply chain issues can reap a number of benefits.

In this context, on-demand manufacturing is a fantastic way to eliminate a number of common issues. Let’s explore further.

What is On-Demand Manufacturing?

This type of manufacturing is different from mass production as it prioritizes producing goods as needed, rather than focusing on quantity. One of the biggest advantages of this is that it drastically cuts down on excess production and inventory.

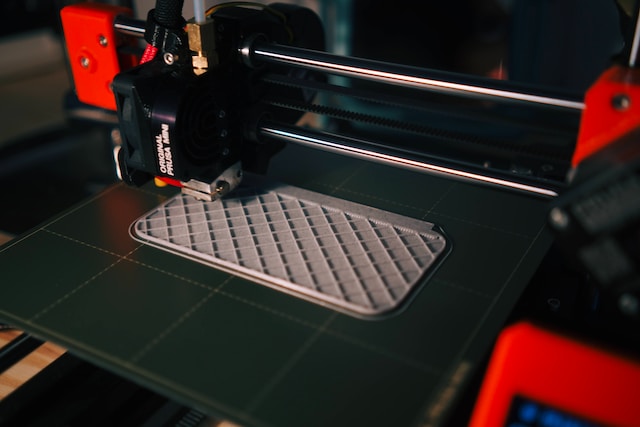

On-demand manufacturing has become more accessible, largely due to technological advancements. The main advancement that allowed this type of manufacturing to spread its wings was 3D printing. It has rapidly advanced beyond its initial perception as a gimmick. 3D printing now allows for part and product creation at an instant’s notice.

If a prototype needs to be made, companies no longer need to send the plans to a plant and wait on their production timelines. Instead, it can be completed in-house or in a dedicated hub in a fraction of the time. Similarly, if a client requires specific parts and spares, they can easily be manufactured on demand.

How Does On-Demand Manufacturing Help Streamline Supply Chains?

Based on the previous section, you can probably guess that the first way that supply chains become streamlined is through inventory management. No longer do supply chains require large inventories to buffer against supply and demand uncertainties. Sure, it offered a safety net, but the storage costs, insurance, and obsolescence of old products when new ones were released were too high.

Similarly, supply chain statistics show that more and more companies are using technology, particularly AI and cloud computing, to boost efficiency. These integrate particularly well with on-demand manufacturing.

According to Fictiv, 85% of supply chain companies have already implemented AI solutions. With on-demand manufacturing, businesses are able to respond much faster to market changes. Remember, supply chains are extremely inertia-heavy. If there’s a sudden development in the market, it can take quite a while to adjust to new factors.

Such issues disappear with on-demand manufacturing. The manner in which supply chains operate makes it so that a lot of time is often wasted. This could occur due to batch production processes, long procurement times, and complex logistics. In that regard, one benefit of on-demand manufacturing is cost savings. The bottom line is always going to be money, and when a manufacturing method allows for substantial savings, it becomes foolish to avoid it.

True, the initial investment in 3D printers and switching over to a different manufacturing model may be complex, but it is often worth it. There is also a significant reduction in lead time, which can be an added bonus to have. This refers to how long it takes for a product to move from production to the customer’s hands.

On-demand manufacturing is clearly part of the powerful new trend that is taking place alongside smart factories. It will be exciting to see how the industry progresses in the coming years.

Frequently Asked Questions

1. What are the challenges in implementing on-demand manufacturing?

As mentioned earlier, the initial investment costs can be challenging for companies with tight budgets. Similarly, to reach professional levels of production with 3D printing, you will have to invest in training for your personnel. You also face the challenge that comes with a rapidly developing field, i.e., your 3D printers may become obsolete as new models come out.

2. Is on-demand manufacturing cost-effective?

It depends on several factors. If one can look past the initial purchase of 3D printers and training, on-demand manufacturing can significantly cut costs. You would no longer need to worry about overproduction. This tends to be a major waste when new generations of products are released and the market no longer cares for the older models.

Conclusion

For many industries, there is no escaping the traditional supply chain model. Moreover, there are many instances where it is simply cost-effective to manufacture en-masse. However, if on-demand manufacturing can work for your business or company, it can be worth investigating its viability.