Effective management of a fleet is crucial for any construction company looking to boost productivity, streamline operations, and stick to project timelines. A game-changing technology in fleet management for the construction industry is GPS tracking. By integrating GPS tracking systems into their vehicles, construction firms can reap benefits that enhance their fleet management practices.

1. Tracking Vehicles in Real Time

A key advantage of GPS tracking in construction fleet management is the ability to track vehicles in real-time. Through GPS technology, fleet managers have access to current information about each vehicle’s location on the field. This feature not only allows them to monitor where their assets are but also provides a detailed history of their movements over time.

Real-time vehicle tracking empowers fleet managers to optimize routes and respond quickly to issues or emergencies. It helps enhance efficiency by assigning the closest available vehicle for new tasks.

2. Enhancing Driver Safety and Compliance

Safety measures for drivers and equipment on job sites are priorities for construction companies. Using GPS tracking systems helps ensure that drivers follow planned routes and speed limits, which reduces instances of detours or speeding.

Moreover, GPS tracking devices can monitor driver behavior, like braking or acceleration. Fleet managers can then analyze this information to evaluate drivers based on their performance and offer personalized coaching when needed.

Additionally, GPS tracking aids companies in monitoring driver compliance with hours of service regulations by recording time spent driving. This ensures adherence to requirements regarding driver fatigue and helps avoid penalties associated with violating workplace safety rules. It also prevents use outside working hours or at off-site locations.

3. Efficient Dispatching and Delivery Management

GPS tracking systems offer a view of each vehicle’s location at any given moment. This allows dispatchers to optimize delivery schedules by selecting the right vehicle for each task based on proximity and availability.

Efficient routing made possible by GPS tracking not only cuts down on fuel consumption and emissions but also decreases costs linked to unnecessary mileage. This optimization leads to faster deliveries, improved customer satisfaction, and enhanced revenue opportunities for construction firms.

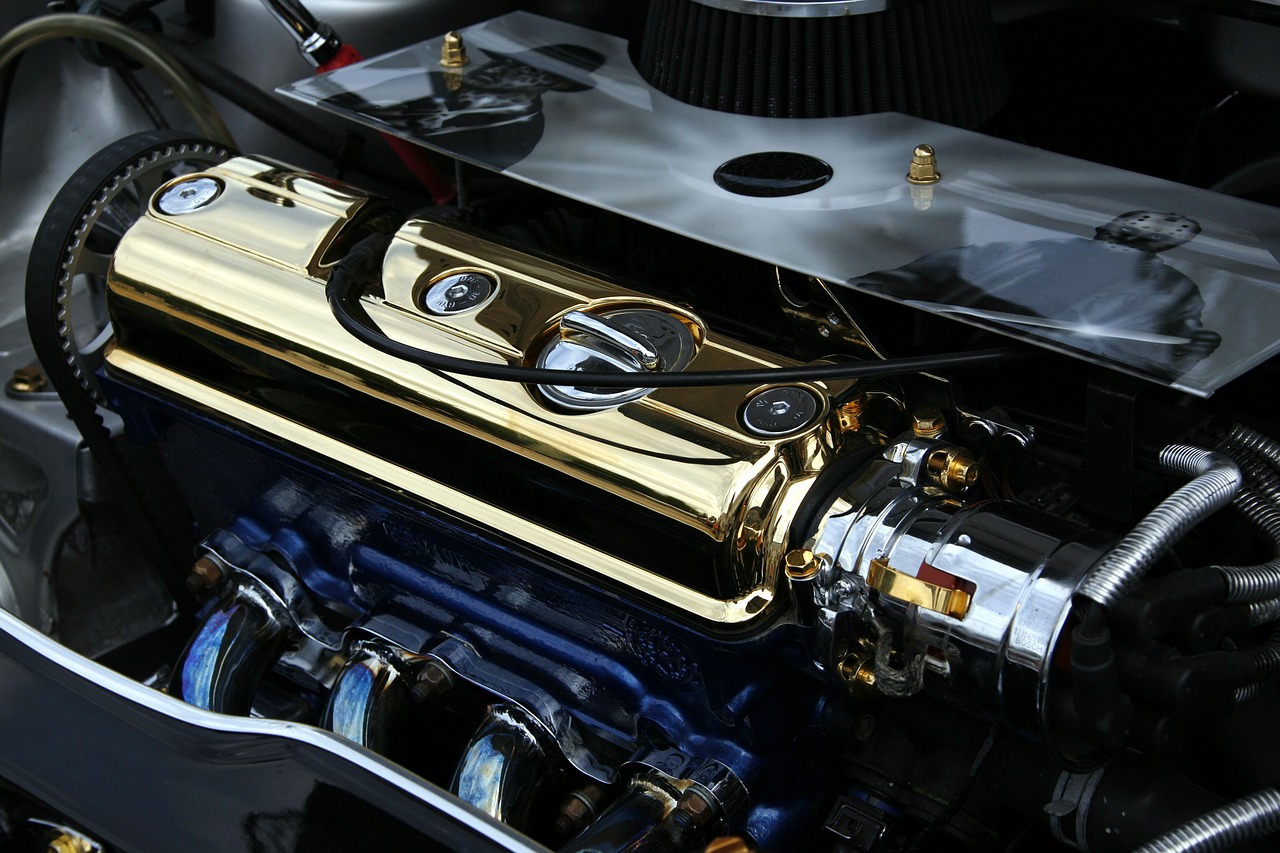

4. Preventive Maintenance and Asset Utilization

By integrating GPS tracking technology into fleet management, construction companies can proactively address maintenance needs for their vehicles and equipment.

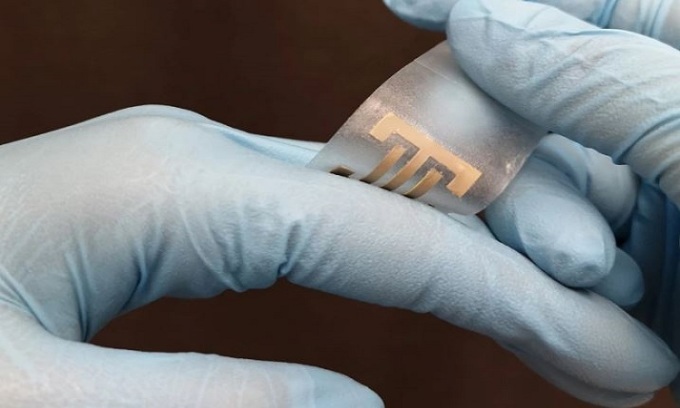

Telematics systems can send notifications for maintenance tasks based on usage or time intervals, preventing breakdowns that may disrupt operations and lead to costly repairs. GPS makes it easier to locate machinery and address it quickly.

Furthermore, by managing asset utilization using GPS tracking data, construction firms can spot equipment or vehicles that are not being fully utilized. This insight enables them to make informed choices about reallocating resources across projects or even selling machinery.

5. Enhanced Theft Prevention

Construction sites are at risk of theft because valuable machinery and equipment are often left unattended outside working hours. By attaching GPS tracking devices to vehicles and equipment, construction companies enhance security measures by monitoring stolen assets in real time.

In case of theft, fleet managers can promptly alert law enforcement about the location of the stolen item using GPS coordinates. This significantly boosts the chances of recovering stolen assets while reducing losses due to theft.

6. Enhanced Data Analysis and Reporting

Apart from the advantages mentioned earlier, GPS tracking systems also grant construction companies access to data for analysis and reporting purposes. This abundance of information can provide insights into fleet performance, enabling managers to make decisions based on data that optimize operations.

Analyzing data generated by telematics and GPS, such as vehicle speeds, routes taken, and idle times, allows fleet managers to pinpoint trends and patterns that highlight areas needing improvement. By monitoring fuel consumption and tracking maintenance costs for repair or replacement decisions, managers can optimize fleet operations effectively.

In Conclusion

GPS tracking systems have become invaluable tools in enhancing construction fleet management. By leveraging real-time vehicle tracking capabilities, ensuring driver safety compliance, optimizing dispatching and delivery processes, maximizing asset usage efficiency, and enhancing theft prevention measures, construction firms can achieve productivity cost savings, improved safety records, and overall project success.

Adopting this technology not only helps construction fleets remain competitive but also positions them as industry leaders dedicated to utilizing solutions that streamline fleet operations while prioritizing employee well-being and client satisfaction. Seize the advantages provided by GPS tracking systems; your construction company’s fleet will reap the benefits!