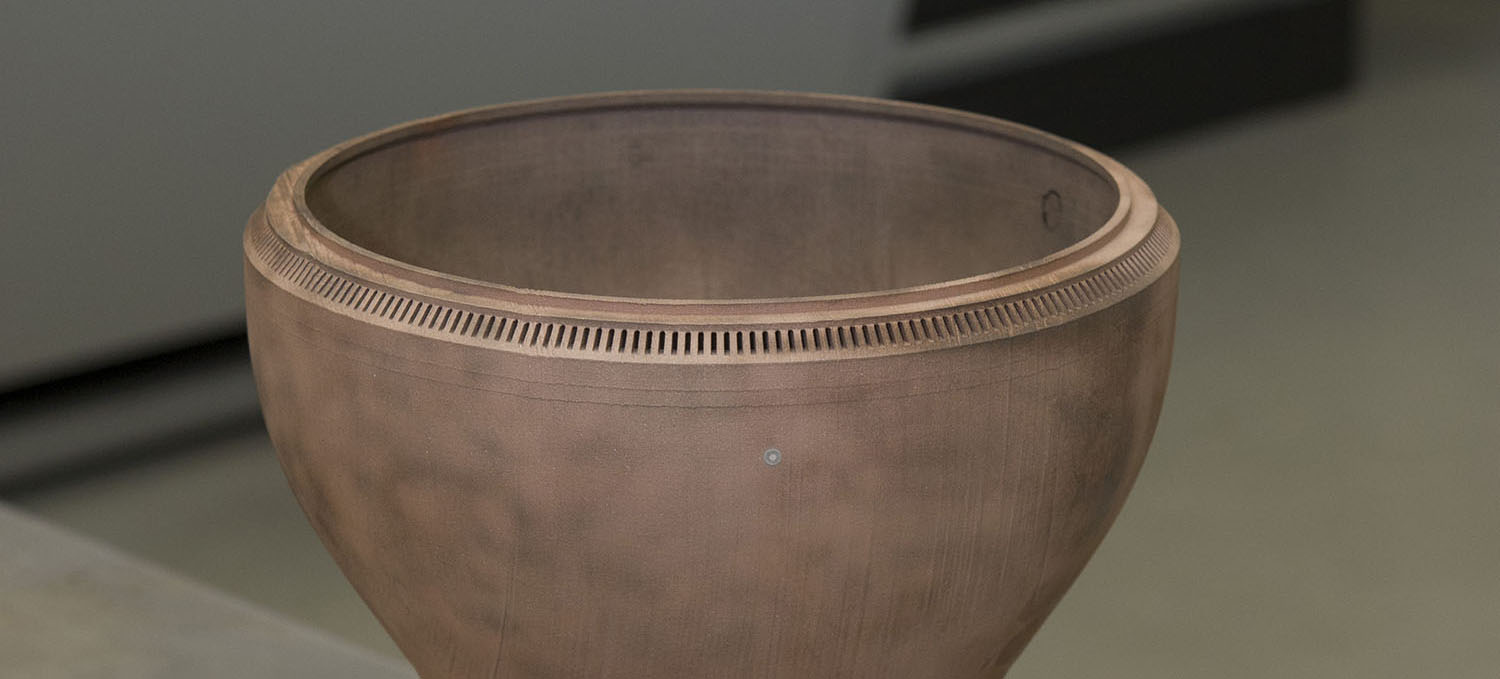

NASA has successfully 3D-printed the first full-scale copper rocket engine part, a combustion chamber liner.

The component is required to operate at extreme temperatures and pressures, making developing the part a rather tedious endeavor.

Chris Singer from NASA explains:

“On the inside of the paper-edge-thin copper liner wall, temperatures soar to over 5,000 degrees Fahrenheit, and we have to keep it from melting by recirculating gases cooled to less than 100 degrees above absolute zero on the other side of the wall. To circulate the gas, the combustion chamber liner has more than 200 intricate channels built between the inner and outer liner wall. Making these tiny passages with complex internal geometries challenged our additive manufacturing team.”

It took 10 days and 18 hours, and 8,255 layers of copper powder to ultimately 3D-print the part, which used a laser beam to selectively melt the copper powder to form solid copper.

A nickel alloy jacket lines the combustion chamber, and the entire thing will be hot-fire tested later this year in order to explore the potential applications of the 3D-printed part.