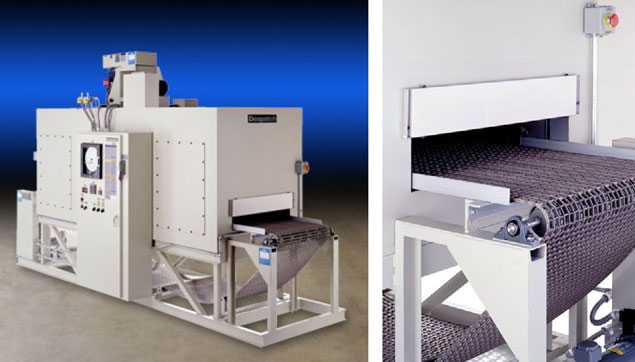

The continuous belt design of conveyor ovens is ideal for large quantities of similar work pieces being processed.

Conveyor ovens from Despatch are designed for process versatility and reliability and are known to provide extremely consistent results thanks to their ability achieve superior air temperature uniformity on all interior parts due to high-volume, vertical down airflow.

While typical applications encompass pre-heating, curing, bonding, drying and heat treating, Despatch has been known to design custom conveyor ovens in order to meet specific client applications, for example drying eyeglass lenses and sterilizing surgical devices.

An optical manufacturer reached out to Despatch about the prospect of purchasing a conveyorized thermal processing oven capable of drying the coatings on its eyeglass lenses.

Despatch acted quickly and was able to design a PC Series conveyor oven with HEPA filtration to meet the customer’s requirements for high-volume production while maintaining a clean internal atmosphere.

The conveyor oven operates at relatively low temperatures and was designed to be compatible with the customer’s robotic loading equipment. The PC Series Conveyor Oven features superior temperature uniformity with temperatures up to 260°C (500°F).

In addition, Despatch designed and manufactured a conveyor oven for a global surgical device supplier, built to sterilize the company’s surgical devices.

The oven comes equipped with a 44” wide stainless steel flat wire process belt that passes through a 650°F heated zone, then through a cooling zone with ambient air cooling.

Further cooling time is provided on an extended outfeed section, while the oven also features HEPA fresh air filters in the heating and cooling zones to help maintain low particulate air within the process chambers.

To ensure the oven was designed and adjusted properly prior to leaving the factory, Despatch test technicians and engineers utilized a set of specialized trays from the customer to execute the FAT acceptance protocol.

The result was a unit approved for shipment and yet another happy customer pleased with purchasing a Despatch industrial oven.

If you’re in the market for one or are interested in learning more, The Ultimate Selection guide to Industrial Ovens will give you an in-depth look into selecting the right oven for your process.