It only takes one little spark and a split second to start a fire or an explosion in industries where flammable gasses or vapors are present.

The potential for explosions is exponentially higher in hazardous environments such as oil refineries, chemical plants, cleaning facilities, and paint shops to name but a few examples.

Two types of specially designed equipment for use in hazardous locations are explosion proof housings and intrinsically safe sensors.

When comparing intrinsically safe sensors to explosion proof housings, first you must understand the basic definition of both offerings.

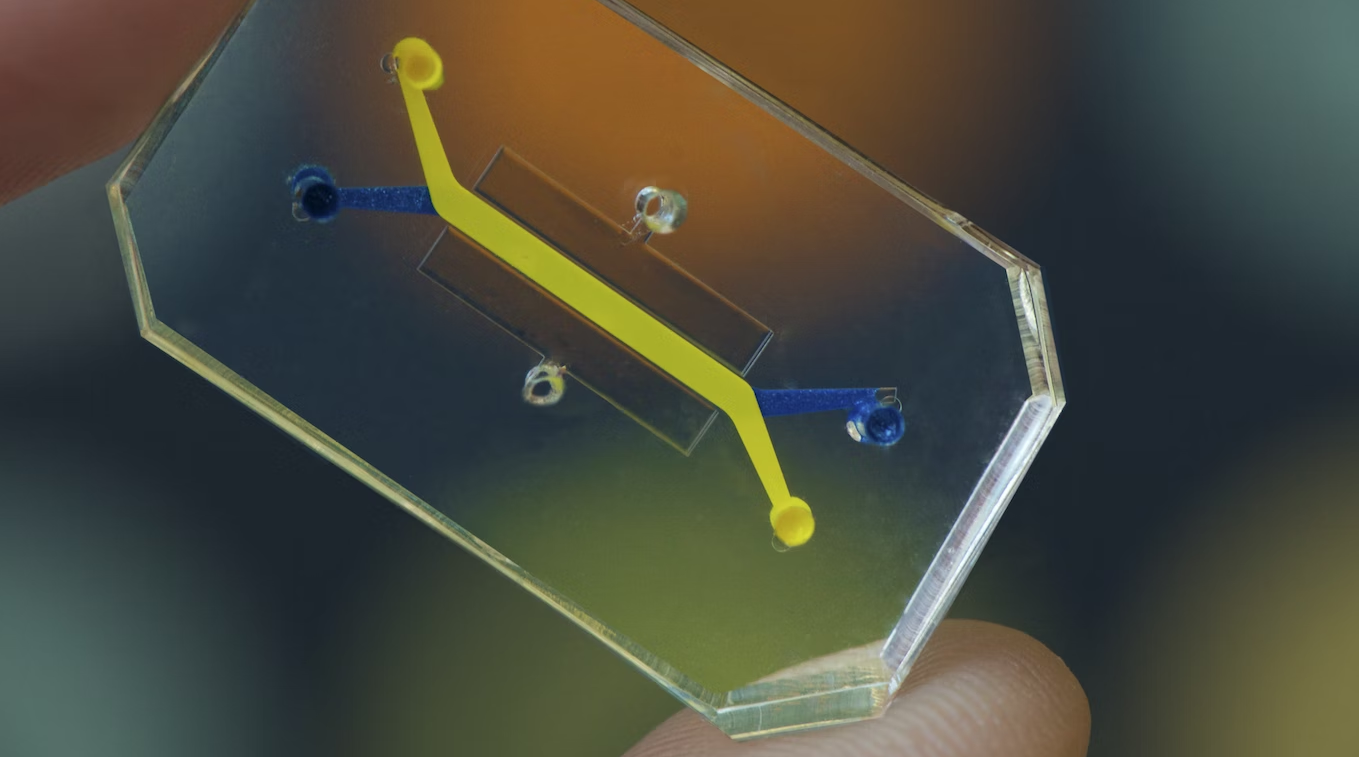

An intrinsically safe component is a tested piece of equipment of low power that is incapable of causing an explosion in a hazardous environment.

On the other hand, an explosion proof component is a tested piece of equipment capable of containing, controlling, and venting any possible flash or explosion.

Explosion proof housings are generally made of cast aluminum or stainless steel and work to safely contain an explosion or internal spark after it occurs to prevent a much larger blast, instead of preventing an exterior explosion from happening in the first place.

Intrinsic Safety (IS) is based on the principle of restricting the electrical energy transmitted into a hazardous area, thereby ensuring that any sparks or heated surfaces that may occur as a result of electrical failures are insufficient to cause ignition.

Whereas explosion proof housings merely work to eliminate more damage being done from the initial blast, intrinsically safe sensors ensure the threat of an explosion is eliminated before it even occurs.

Intrinsically safe is used mostly for very low power applications since the amount of power the equipment receives is typically controlled through the use of intrinsic safety barriers such as diodes, resistors, and fuses sized to limit the energy provided to the device in the hazardous area.

An explosion-proof or flameproof device has no limitations on energy, and this protection method can be used for high-voltage or high-current applications, as well as for devices with high levels of inductance or capacitance. The basic principle of an explosion-proof device is that ignition can occur within an enclosure, but the effects are confined to the enclosure and cannot propagate through flange faces or other openings to the outside atmosphere.

An explosion proof housing is generally heavier than an intrinsically safe device because of the inherent safety provision with respect to containing the explosion.

If a device requires a significant amount of power to operate, explosion proof must be used, but is more dangerous and acts as a damage control protection concept versus intrinsically safe sensors acting as a full preventative tactic.

Ultimately, intrinsically safe systems provide the safest operating environment for personnel and equipment, in addition to being lighter and less bulky than explosion proof housings.

Positek’s Intrinsically Safe sensors provide a unique blend of performance, durability, ease of use, and cost-effectiveness. The typical performance of the sensors is ± 0.25% linearity with temperature stability of ± 0.01%/°C.

Each sensor is supplied ready calibrated which saves installation time. The sensors offer distinct advantages over other sensors such as LVDTs and offer improved durability and robustness compared with potentiometers.

The sensors are designed to survive the most hostile environments without the need for any additional protection and are highly customizable, if necessary, to fit the exact requirements of the application.

Positek features an extensive standard line of mechanical configurations, electrical input and output options, and ATEX certified intrinsically safe electronics for hazardous locations to satisfy a very wide variety of industrial and commercial applications.

Beyond ATEX, Positek is certified by CSA, IECEx, and ANZEx.