The US Department of Defense has created the Defense National Stockpile Center (DNSC) to oversee the acquisition, storage, and management of the inventory stockpiles contained in the National Defense Stockpile. Recently, DNSC has begun using automated management systems to measure and distribute its resources, saving considerable time and money.

Widespread Use Across Industries

Companies, municipalities, and others charged with stockpiling and managing large volumes of materials such as salt, wood chips, corn, limestone, and the like, are now using automated volumetric laser scanning systems to obtain more accurate measurements. These new systems relay data to smartphone apps making the whole process incredibly easy and dependable.

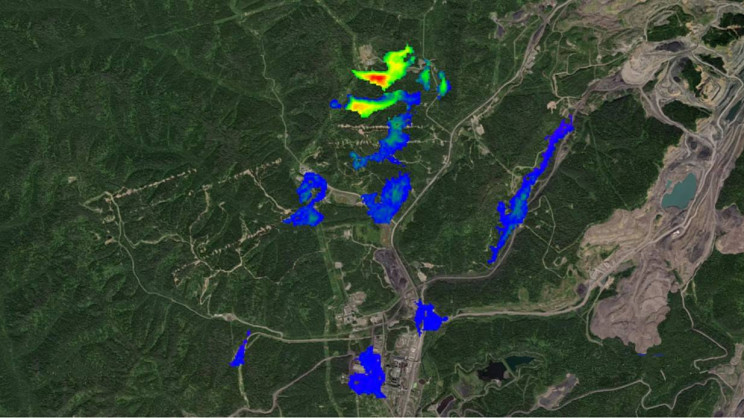

This process is also known as automated stockpile monitoring and management, and the technology provides up-to-date inventory stock levels that can be carried out in less than an hour. The most advanced 3-D scanning methods for stockpile volume measurement use formulas to model the geometry of piles. Data acquisition can be done at ground level or using photogrammetry which uses photography to measure the distances between objects.

Integrating Stockpiles Volume Measurements Into Inventory Management

In addition, the measurement system is integrated into the commodity inventory and order management systems. Efficiently operating any industrial process requires measurement, actuation, recording, and control. One major player in volumetric laser scanner stockpile inventory management is ABB‘s VM3D volumetric laser scanner.

The following video shows a real case of stockpile scanning from SarPoint Engineering.