The vast majority of 3D printing technologies, also known as additive manufacturing (AM), use a layer-by-layer strategy.

But thanks to some rapid improvements in technology and a growing understanding of the process, 3D printing has started to rapidly expand on the multi-material capabilities.

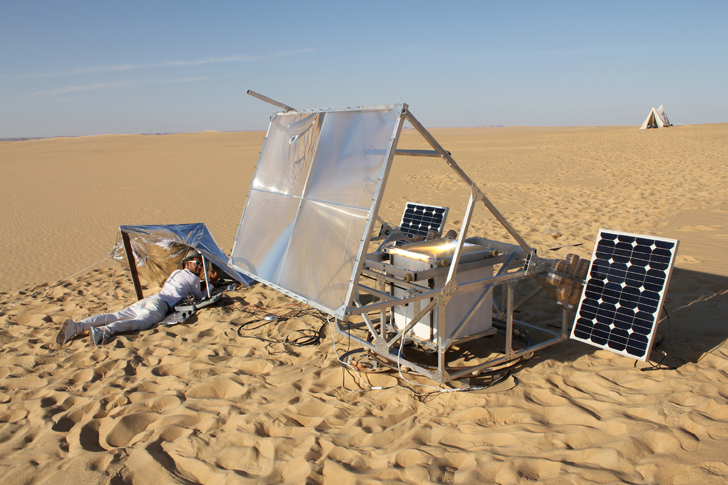

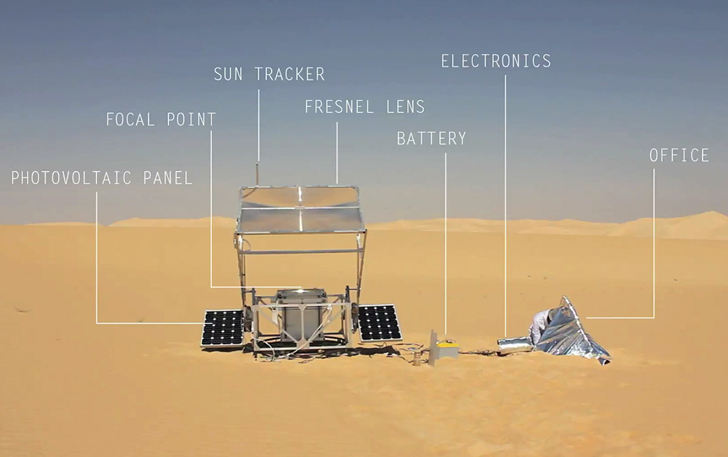

Now, Markus Kayser, a former design student at the Royal College of Art in London, has invented an awesome 3D printer that prints objects from materials found in abundance in the desert, i.e., sun and sand.

This amazing 3D printer is dubbed the Solar Sinter

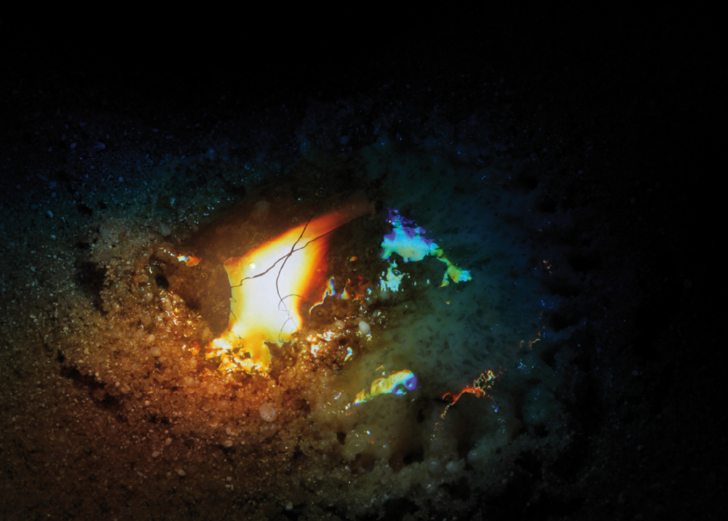

It uses sunrays via solar panels to heat silica sand to its melting point. When cooled, it solidifies into glass objects. Kayser tested the Solar Sinter in the Egyptian desert.

The process is called 3D sintering. Sintering is one of the main processes behind conventional 3D printing that uses a laser to melt and transform materials like resin or plastic powder into solid objects. But Kayser replaced resin/ABS plastic and laser with silica sand and sunrays to create 3D glass objects.