What are 3D Printed Tires?

The world is at a stage when it appreciates sustainability; this bid is the core on which the additive manufacturing companies are based. In a bid to drive sustainability for the near future, companies like Michelin are investing a substantial amount in producing 3D printed tires. With the various strides taken, additive manufacturing is gaining more ground in the automobile industry.

3D printed tires are made with the selective laser sintering (SLS) technology, by employing the use of biodegradable materials, which includes orange zest, bamboo, molasses, wood, and natural rubber. This 3D printed tire, according to Michelin, is known as the “Vision.” Unlike the traditional tires used on a large scale in the world, the Vision is more solid, sponge-like, and looks like a 3D print, which is molded to be wheel-like in shape. For this type of wheel, there is no inner tube which is used in the tires to maintain its structure by injecting air into it regularly.

The extensive use of these 3D printed tires would probably not be feasible in the near future, but with continuous development, in less than a decade, many vehicles will roll out, using this system in the design.

Self-repairing Shoes

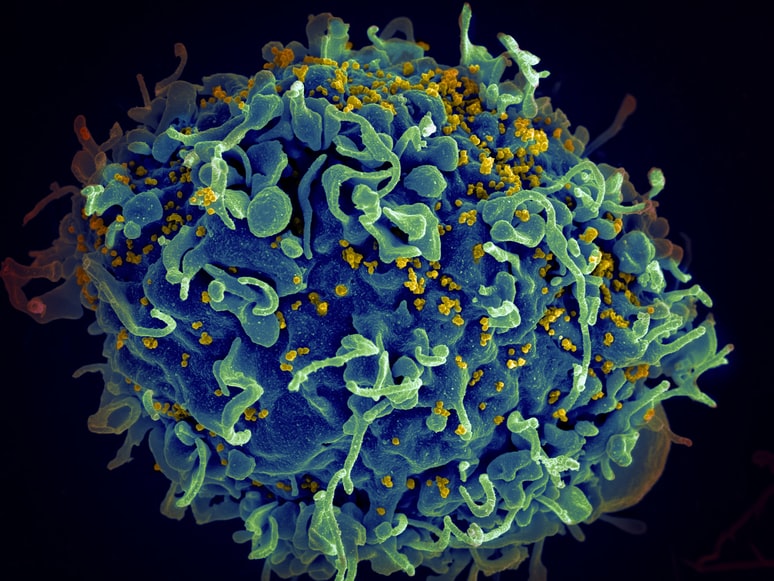

Over the years, researchers have embarked on the engineering of a rubber that self-repairs and this is aimed to be printed in 3D. With this technology, the material can self-repair in a matter of hours. The process underlying 3D printing is photo polymerization. Photo polymerization is a process that makes use of light to solidify a liquid resin. It is attained through reactions with a chemical group known as the thiols. When an oxidizer is subsequently added to the thiol, they are transformed and form disulfides, which is the chemical group that is able to self-repair. This is the underlying process behind the self-repairing shoes.

3D Printed Tires and Self-repairing Shoes: What would change?

It is an eco-friendly approach to designs.

3D designs for tires and shoes are leaping forward in the production industries to provide a more sustainable solution. The companies are set up to produce utilities that would help sustain the environment, a solution to the ecological sector of various industries.

One major concern of the automobile industry now is how to create vehicles that are environmentally friendly, which is why the push for electric cars has been high in recent years, with various companies like Uber, Tesla, and Lyft testing prototypes and innovating better functionalities. With the additive manufacturing techniques, parts of automobiles, especially the tire that is initially made of non-biodegradable materials, would be produced. Recently, the EU initiated a project worth 2.7 million Euros to produce cars and other infrastructures with recycled 3D printed materials. This has bolstered the poise of researchers to discover and innovate more in the additive manufacturing eco-space. The environment is a big challenge that the automobile industry must deal with and 3D printing could be the solution.

It’s a game changer.

With the use of 3D printed shoes, there would be no need to constantly change shoe soles or get rid of shoes when they get torn or worn out. An oxidizer could be easily used to reform the shape that is lost, and in a couple of hours, the shoe would be self-repaired. There would be less frequent replacements needed for shoes and if they are ever replaced, the shoes are biodegradable and would not constitute health hazards.

When the 3D printed tires are extensively deployed, it will provide a new look to the automobile space, as it allows for sleeker and customized designs. Tires can be printed in custom designs on wheels in no time. The additive technology is the perfect technique of manufacturing, since complex designs that seemed impossible for traditional tires would be accomplished in record time. This technique also enables wheels to be designed and optimized to adapt to various road conditions, as well as accomplishing the eco-friendly aim.

Author Bio:

Nichole Heydenburg is a Content Writer for Apex Waves, an electronic test equipment company based in Cary, NC.

Twitter: @Apex Waves