“Necessity is the mother of invention” is as apt for new wind turbine de-icing systems as for those created decades ago for planes.

Modern day windmills and their blades are taller and larger than ever before and run 365 days a year through rain, sleet and snow with temperatures that drop below zero. According to industry reports, the presence of ice on blades can cut the production of electricity by 20% a year in cold climates where ice is present for several months or more a year.

Protecting wind turbines from ice requires a de-icing system. The leading edge of a wind turbine blade builds up ice and in order to keep the blade spinning and generating electricity, de-icing must continually take place. Imagine workers scaling a wind turbine to de-ice its blades manually! There are currently six different solutions to wind turbine icing: hot air, coating paint, blade control systems, built-on or integrated heating panels, geometrical enabled blades and new nanomaterials.

Perhaps the most interesting systems for de-icing blades involve biomimicry and nanotechnology. Scientists have been developing “superhydrophobic coatings” in which water droplets roll off of surfaces in the same way this occurs on specific types of leaves. In essence, the molecular surface of these coatings do not permit binding with H2O which simply runs off.

A company called Kelly Aerospace has been creating de-icing systems for planes for many years and is now providing de-icing solutions to the wind power industry. According to the company, its Wind Turbine Ice Protection System (WTIPS):

- Sheds ice during operation

- Does not require shut down during icing conditions

- Protects blades from leading edge erosion

- Involves simple external installation on blades

- Uses PLC controlled deicing system

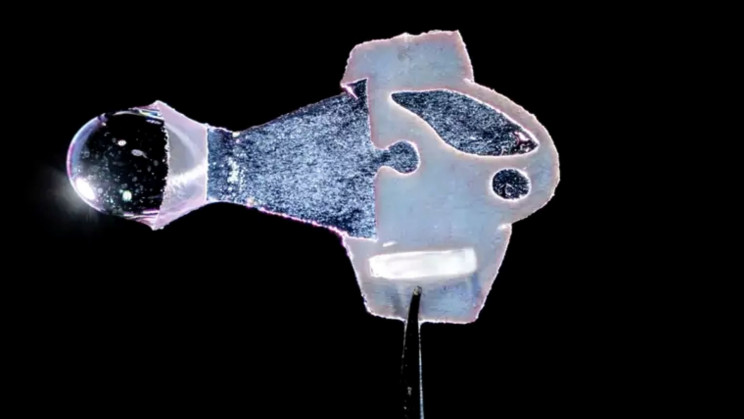

- Uses a flexible graphite foil

- Limits laid in balances when ice is present

- Reduces wind turbine vibration and wear

WTIPS measure relative humidity, blade temperature and ambient temperature to determine the right time to de-ice. Once de-icing begins, it only takes 7-14 minutes for the cycle to complete.

[relatedYouTubeVideos relation=”title” max=”1″ class=”horizontal center bg-black” showVideoTitle=”true” showVideoDescription=”true”]