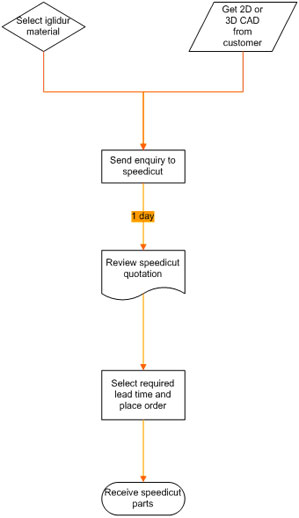

A new custom machining process from igus called “speedicut” expedites lead time on custom components by taking a drawing from a customer and then efficiently creating the parts using iglide bar stock materials.

Speedicut uses a 3D model to produce a simple and fast quote, resulting in parts that are ready to be delivered within just a few weeks. Not to mention, there is no minimum order, so custom components can be ordered to fit the exact needs of each individual client.

The name speedicut is the perfect fit for a variety of reasons. First of all, it makes economic sense to machine some parts over molding them when you have the speedigus® tooling system and standard iglide materials at your disposal.

In addition, with a hi-tech machining cell, complex parts can be machined very quickly to a custom design. Lastly, the speedicut quotation and production processes are, you know, speedy!

Unless the part is unusually complex, you will receive a quotation within one working day.

Production can also be as fast as one day. Numerous options are given within the speedicut quotation, but the maximum lead time for 100 speedicut parts is 10 days. If more than 100 parts are required, then the lead time is given in the quotation, but 100 parts will always be ready within 10 days.

What are the dimensional limits?

This depends on the iglide material selected, as the stock bars are not available in every dimension in all materials. In general, if the part can fit into a circle of 100mm diameter then a speedicut option can be offered.

What tolerances can be achieved?

When a 2D drawing is submitted, then speedicut uses the tolerances quoted on the drawing, and any differences would be mentioned in the quotation. If a 3D model is submitted, then, the expected tolerance for a dimension on a well designed part is +/- (0.1 + 0.005mm/mm). For example, a length of 10mm would have a tolerance of 0.1 + (10 x 0.005) = +/-0.15mm. This 3D tolerance statement is the same as speedigus® molded parts.

What is the advantage of speedicut over other machining companies?

The big difference is that speedicut uses standard iglide tribological materials, so all the life calculation programs offered by igus® can be used to optimize material selection. The other major advantage of speedicut is the speed in which you receive a quotation and parts, working with either 2D or 3D drawings.

Why should I use speedicut instead of traditional prototyping methods, such as SLS?

Speedicut uses real igus® materials, which are designed for long life and durability. The materials used in rapid prototyping methods are developed for ease of manufacture, not for long life. With the speedicut and speedigus® services, igus® is filling this gap.