The most interesting companies are those with roots deep in the past that have kept up with technological changes through time and continue to be leaders in the development of new technology. Two pioneers in the manufacturing of heavy lifting and chain systems were Carl Rieger and Friedrich Dietz, from the Aalen region of Swabia, Germany, who began their company, today known as Rieger Und Dietz, or RUD, during the days when walks in the countryside were accompanied by the loud and smoky presence of blacksmiths heating and fashioning raw metal into tools.

Since the 1950s, RUD has been an international industry leader in the manufacture of close mesh, high-alloy, drop-forged, steel, “wear links” that wrap around tires to protect treads and sidewalls. During this time, RUD has consistently delivered innovative designs to keep tires and the considerable investment in them, protected.

Fast forward to the 1970s and the German mining industry, where the main cause of accidents was related to cheap and low-quality eyebolts, some of which were homemade. To reduce accidents, RUD engaged in the development of a more dependable industry standard. With decades of experience in the heavy lift industry at the time, RUD developed specialized lifting equipment to reduce risks associated with eyebolts.

Today, RUD makes, among others, tire protector chains, fences, furniture, conveyor systems, and sling and lashing systems for chain hoist manufacturers. As cranes have become larger and lift ever heavier objects, RUD has continued to innovate by developing specialized lifting products.

Smart Chains

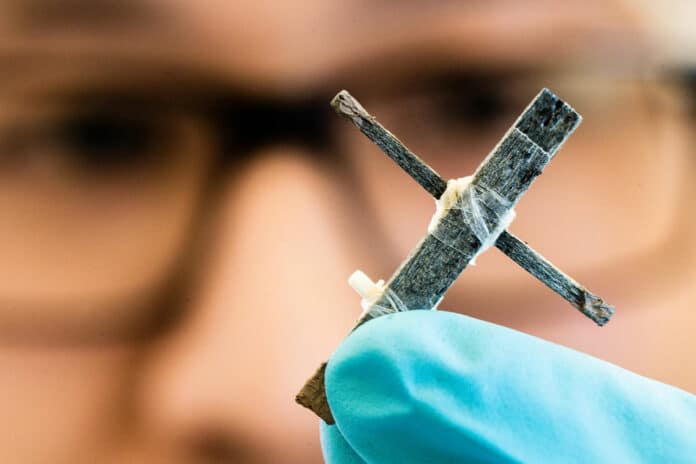

Recently, RUD pioneered the RUD-ID Point, a small RFID chip wirelessly connected to a computer tracking system, which is incorporated in all of its lifting points and hooks. The chips are just 8 mm in diameter and 3.25 mm thick and have a 13.86 MHz transponder embedded in master links, hooks and lashing points. These RUD-ID Points stay with products throughout their lifetimes and are tracked through online systems, USB port devices, tablet computers, LCD displays or even cell phones via Bluetooth, providing key information on the “health” of component or chain assemblies.

The full range of RUD products includes: conveyor and drive systems, lifting and lashing means, hoist rings, military technology, mining, connectors, hoist chains, snow chains, automatic tire chains, tire protection chains and Erlau outdoor furniture.

Related articles on IndustryTap:

- RUD Chain Implements RFID Tracking To Keep Heavy Lifting Safe

- Amethyst Hotels: Dutch Firm “NL Architects” Offers a Gem of an Experience in Its Proposed Chain

- 57% Less Power Needed With The E-Chain. The Smooth, Quiet and Exceptionally Long Cable Carrier

- Breakthrough Safety Upgrades to Die Lifting and Transfer Practices Protect Against Catastrophic Injuries

References and related content: