Many engineers are shifting from traditional two-dimensional (2D) fabrics to advanced composites based on 3D woven fabrics, for applications that call for superior strength, elasticity, and durability.

Three-dimensional (3D) weaving can produce complex, single-piece structures that are tough and lightweight, and are perfect to be used for wide range of applications.

What is 3D weaving?

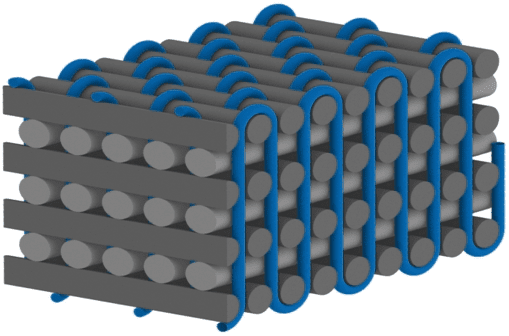

Unlike two-dimensional (2D) fabrics which are woven in two dimensions — the X axis (length) and the Y axis (width), 3-D woven fabrics includes weaving through the thickness, or the Z axis. This thickness in 3-D woven fabrics is attained by forming multiplayer using multi series of warp and multi series of weft, both intersecting at regular 90 degree angle.

3D weaving is an emerging technology and because of its benefits like weight reduction, elimination of de-lamination, reduced crack risk, lower production time, and cost reduction, these are used as composite bases in numerous industries and applications.

Common Uses and Applications of 3-D woven fabrics:

- 3D woven composites being lighter than metal structures are ideal for aircraft and airspace applications.

- They are also useful in space structures like missiles, satellites and rockets, as 3D fabrics have all the required specifications like light weight, high stiffness and low coefficient of thermal expansion.

- They are commonly used in medical technology, like artificial veins and arteries.

- Because of their toughness and durability, these fabrics are used in numerous industries and applications like transportation, heavy industrial, ballistics, marine sectors, etc.

- 3-D woven fabrics are also used in sports related material, like tennis rackets, hockey sticks, skateboards, skates, snow and water skis, and lot more.