This type of product is quite common and can be used in a wide variety of industries, as well as other spheres. Naturally, the main applications for wire rod are manufacturing, the energy sector, and construction.

Wire Rod Manufacturing

Wire rod is a hot-rolled wire with a diameter ranging from 5.5 to 42 mm. Rods are made of carbon steel, aluminum, and copper of ordinary quality. The cross-section of wire rod can be hexagonal, round, semicircular, or square. The main factor that determines the technical parameters is the type of material it is made of.

Wire rod is made by drawing hot metal through shafts. The shafts form and compress the metal from different sides, thus turning a piece of metal into a long, thin wire. At the end of the rolling mill, this wire is wound on a special winder, with the help of which the rod is rolled into skeins for further cooling. The production method is called ‘hot;’ however, the metal is not pre-heated – it is heated when passing through the shafts.

After rolling, the rod must be cooled. This process can go in two ways: through air or accelerated cooling. Air cooling occurs naturally in contrast to accelerated, which requires special fans. After cooling, the rod is ready for storing.

High-quality requirements are imposed on wire rod. For instance, if the rod is manufactured for further wire production, then it should be free of burrs or other deformations. If they are present, the rod can still be used for other purposes.

Apart from that, voids and bubbles may appear on the surface of the rod, significantly reducing the strength of the material. The quality of the product is also adversely affected by decarburization, which may occur when the rod is heated.

There are other mechanical defects that may occur; some of them only affect wire rod prices, while others make it unusable. Therefore, production is controlled carefully, and the rod goes through constant quality control at all stages of manufacturing.

Usage of Wire Rods

There is a variety of applications for steel wire rod, such as:

- Aviation

- Engineering

- Reinforcing concrete structures

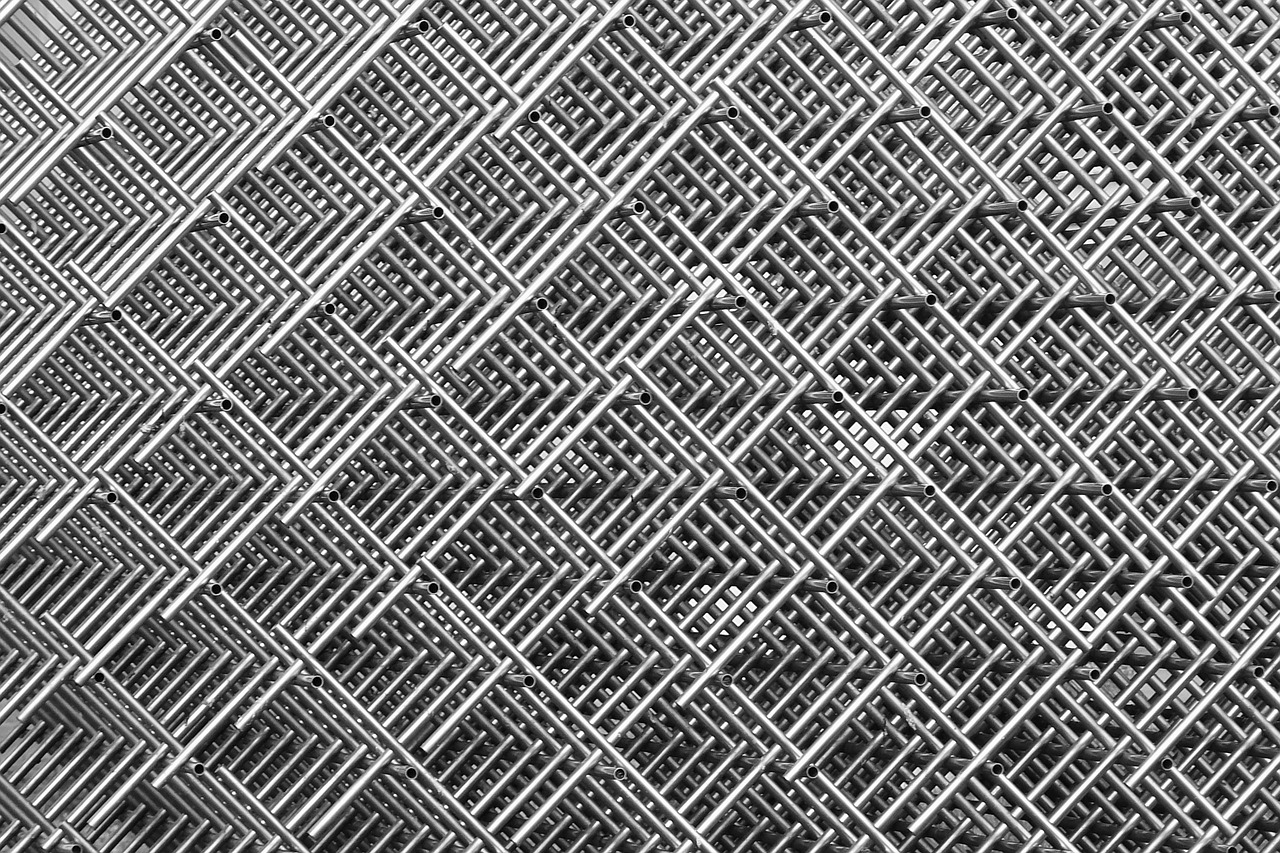

For example, in the manufacture of reinforcement cages; square, round, or rectangular-shaped assembly clamps are made from wire rod. With the help of reinforcing cages, monolithic columns, girders, belts, cross-tops, and lintel strip foundations are reinforced.

In addition to the use of wire rod in reinforcing cages, it is also used in the manufacture of welded reinforcing mesh for monolithic structures, such as concrete floors and screeds.

Steel rods are also used when laying bearing walls or walls of brick, cinder, foam, or gas block. Depending on the concrete used for masonry, steel wire is put into each 2nd-4th layer of mortar, thereby enhancing the overall strength of the masonry. Thus, the rod performs the role of reinforcing the structure.

Apart from that, wire rod is used in the production of electrodes and wires for welding, as well as the manufacture of telegraph wires, ropes, and cables. For such applications, aluminum and copper rod fits best. Most often, such wire is used in power supply systems. In order for rod not to affect the operation of these systems, it must be plastic and well deformable. These characteristics play a key role when choosing the right diameter of the rod.

Guest Author: Metinvest Holding