As the image above shows, a container ship on the verge of capsizing would require the most experienced crane operators moving skillfully and quickly to avert disaster, perhaps preventing the loss of millions of dollars of cargo and human life. But what if the most skilled operators were not nearby?

Now, every licensed operator can have hours of mandated experience dealing with the most extreme situations through virtual reality training. The most difficult of disasters can be re-created in a virtual world and “practiced on” over and over.

IndustryTap recently covered “Heavy Equipment & Crane Catastrophes Often Preventable” and a number of articles on virtual reality including Oculus Rift, Virtual Windshields and the use of virtual 3D Modeling by SpaceX to revolutionize rocket engine design and manufacture. Now industries from construction, defense and offshore energy, to ports and robotics are fully embracing virtual training to augment skills of operators, improve efficiency and reduce accidents.

Standards Based Virtual Training

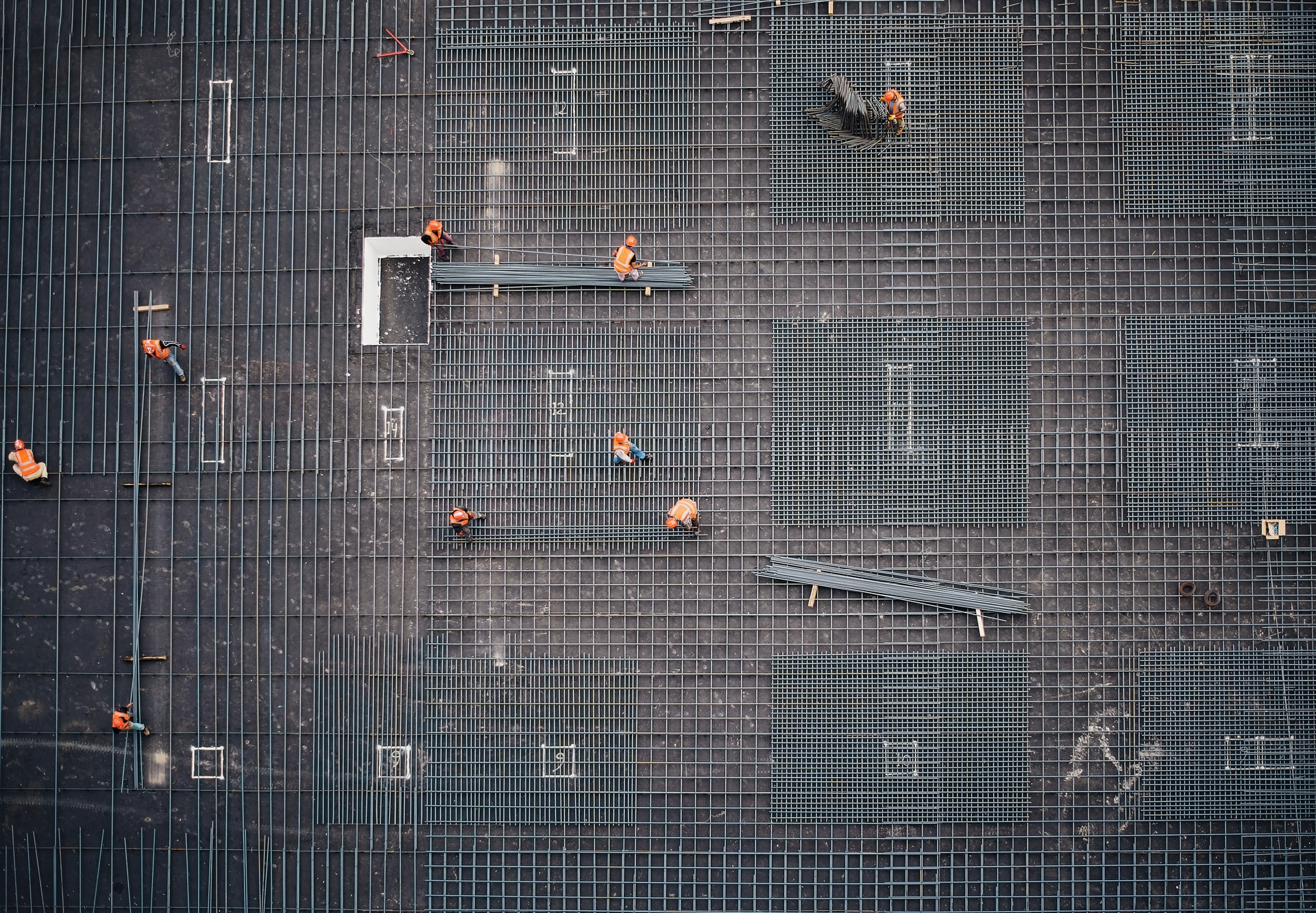

In the heavy equipment industry, for example, companies like John Deer are using cutting-edge simulator technology to improve operator familiarity with hardware helping instructors and operators identify weak or inefficient use of heavy equipment.

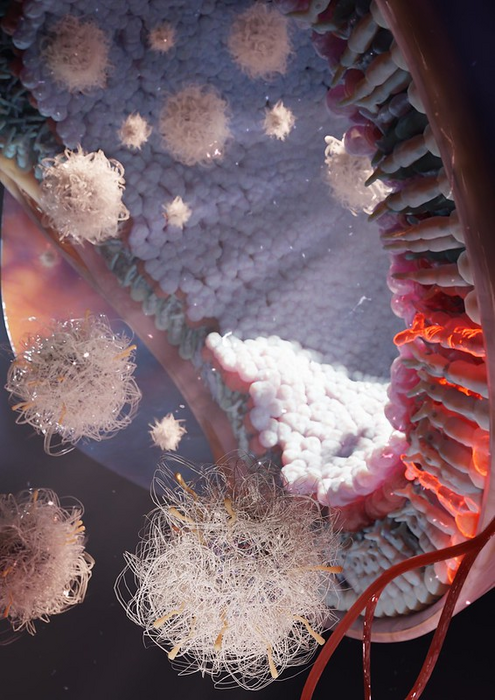

Virtual reality simulators re-create a world identical to the real one, helping crane operators develop muscle memory of both routine and complex operations. Instructors and operators review output identifying inefficiencies or weaknesses which subsequent training can be tailored to improve.

Simulator applications include: excavators with dynamic terrain and digging, packbots, tower cranes, ship-two-shore cranes, harbor mobile cranes, port/quayside cranes and many more.

CM Labs: Over One Thousand Simulators

CM Labs, one of the leaders in interactive 3D training systems, has developed over 1,000 custom training solutions to mirror equipment and processes across a wide range of industries.

Operators are able to practice the most challenging of scenarios in safe and controlled circumstances. Training systems measure each operator against of list of critical criteria and red flag unsafe or dangerous actions as operators respond to unpredictable situations.

When companies have new environments or equipment, interactive 3D simulators are created and operators trained before they go to the job site.

Related articles on IndustryTap:

- One Of World’s Biggest Heavy Lift Vessel Moves 9,750 Ton Topside Onto Oil Platform (Video)

- World’s Largest Offshore Oil Platform an Engineering Masterpiece

- World’s Largest Ship Ever Built and First Floating Liquefied Natural Gas (FLNG) Platform to Begin Drilling in 2017

References and related content: