Ice Pigging is a cost-effective method of cleaning pipes using an ice water slurry. The method has been widely adopted by the global water industry and is also gaining the interest of other industries, in particular, Food & Beverage, Automotive, and Oil & Gas.

What is Ice Pigging?

It is often necessary to clean pipes of sediment and other deposits. Prior to the development of Ice Pigging, the main techniques were flushing using high-velocity water, swabbing (pigging) using a solid object such as a sponge or plastic swab passed through the pipe using water pressure, and air scouring. All of these methods have drawbacks. Flushing uses large volumes of water and is unsuitable for large pipe diameters; swabbing is disruptive and there is the potential of pipe blockages; and air scouring is only suitable in certain circumstances and can damage pipe walls.

An ice pig is ice-water slurry which is pumped slowly through pipes. It scours the pipe walls, collecting debris which is carried with the flow, until it is removed along with the ice pig. Effectively, the ice pig is a flexible plug that can change its shape according to the pipe, making it able to negotiate bends and changing pipe diameters. It maintains its ability to clean while negotiating these topographical changes and can never become stuck. The worst case scenario is an ice block, which will naturally melt. Ice Pigging uses only a fraction of the water used in flushing, and it can be introduced to the pipe and removed with minimal disruption.

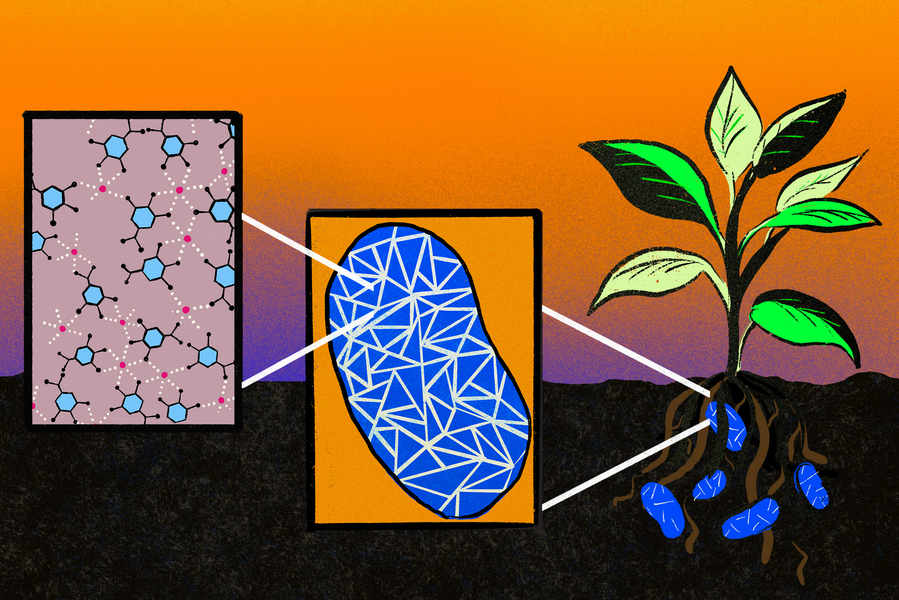

The Science of Ice Pigging

The ice pig is effectively a mass of small ice crystals which are abrasive and able to scour debris from the pipe. To maintain them as crystals and to prevent them from forming solid ice, freezing point depressants are used. The specific depressant depends on the application. For instance, salt (sodium chloride) is a common choice but sugars, alcohols and other materials can be used depending on the particular industry. Typically the slurry contains between 50% and 90% ice.

Other materials can be added to the slurry, for instance, sand can be added to increase its abrasive properties, chlorine to help remove biological contaminants, and corrosion inhibitors.

Applications in The Water Industry

Ice Pigging has been adopted by the water industry in many countries including the UK and mainland Europe, USA, Australia, Japan and Chile. During 2014, it was used to clean 760 km of pipes with diameters ranging from 6 to 700 mm.

Applications in Other Industries

Aqualogy can offer Ice Pigging to a wide range of industries. These include Food & Beverage, Automotive and Oil & Gas. In addition to efficient, environmentally-friendly pipe cleaning, potential benefits to these sectors include reduced effluent, product recovery, and anti-corrosion treatments.

About Us

Aqualogy, a subsidiary of Suez Environnement, is the technology and solutions division of Agbar, one of the world’s largest water and wastewater companies with products covering the entire water cycle. Working with a wide range of customers in the industrial and utility sectors, Aqualogy is focused on tailored and integrated process solutions for measurable results.

The Aqualogy group operates in 18 countries in the world and has over 140 years’ experience in the water industry. Together, the group serves over 26 million inhabitants and operates over 90,000km of distribution networks and 41,000 sewerage networks.