Some might be perfectly happy with a sheet of clean ice: it’s beautiful enough in its own right. But of course, nothing is simple.

Throw in two rosters or 46 muscular, athletic NHL hockey players, 4 on-ice officials, three periods of intense skating, mixed in with sweat and blood and the warm bodies of 19,800 delirious fans, quaffing down beer and hot coffee, eating salty buttery hot popcorn and steaming hot dogs and shouting at the top of their lungs. Needless to say, the ice crew has its work cut out for it.

Frank J. Zamboni was born in Utah on his parents’ farm where he and his brother learned to work on farm machinery. The brothers went into business and expanded from machinery into electrical services and supplying of custom refrigeration units to the dairy industry. In the 1930’s, the brothers began supplying ice for moving fresh produce via railroad from California’s rich farmland to the rest of the country.

Turning Lemons Into Lemonade

In 1935, Willis Carrier patented refrigeration and air-conditioning technology which put an end to the Zamboni’s business. At this time, a cousin named Peter opened “Iceland,” one of the largest skating rinks in the country. The skating rink became popular and the three Zambonis found themselves having to shut down skating for 90 minutes at a time to resurface the ice by sweeping up chips and smoothing gouges.

It was hard work and once again necessity was the mother of invention. By 1949, the three Zambonis tinkered and tinkered until they came up with a machine that could do the work automatically. Olympic skating champion Sonja Henie visited Iceland to practice and was amazed to see the automated machine creating a smooth surface in just minutes. Henie purchased her own Zamboni and the rest is history.

How Does the Zamboni Work?

There are four stages in the Zamboni process: shaving, collecting, washing and resurfacing.

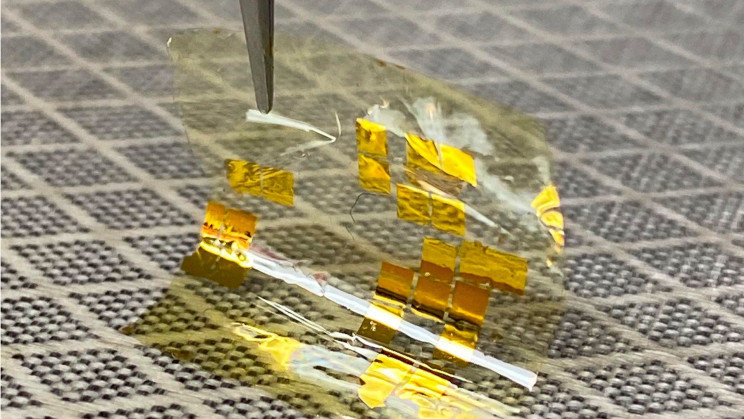

Frank J. Zamboni & Company created a video to show how the machine does its job. Step 1 involves shaving a thin layer from the surface of the ice. This is done with a horizontal screw or auger that gathers shavings behind the screw.

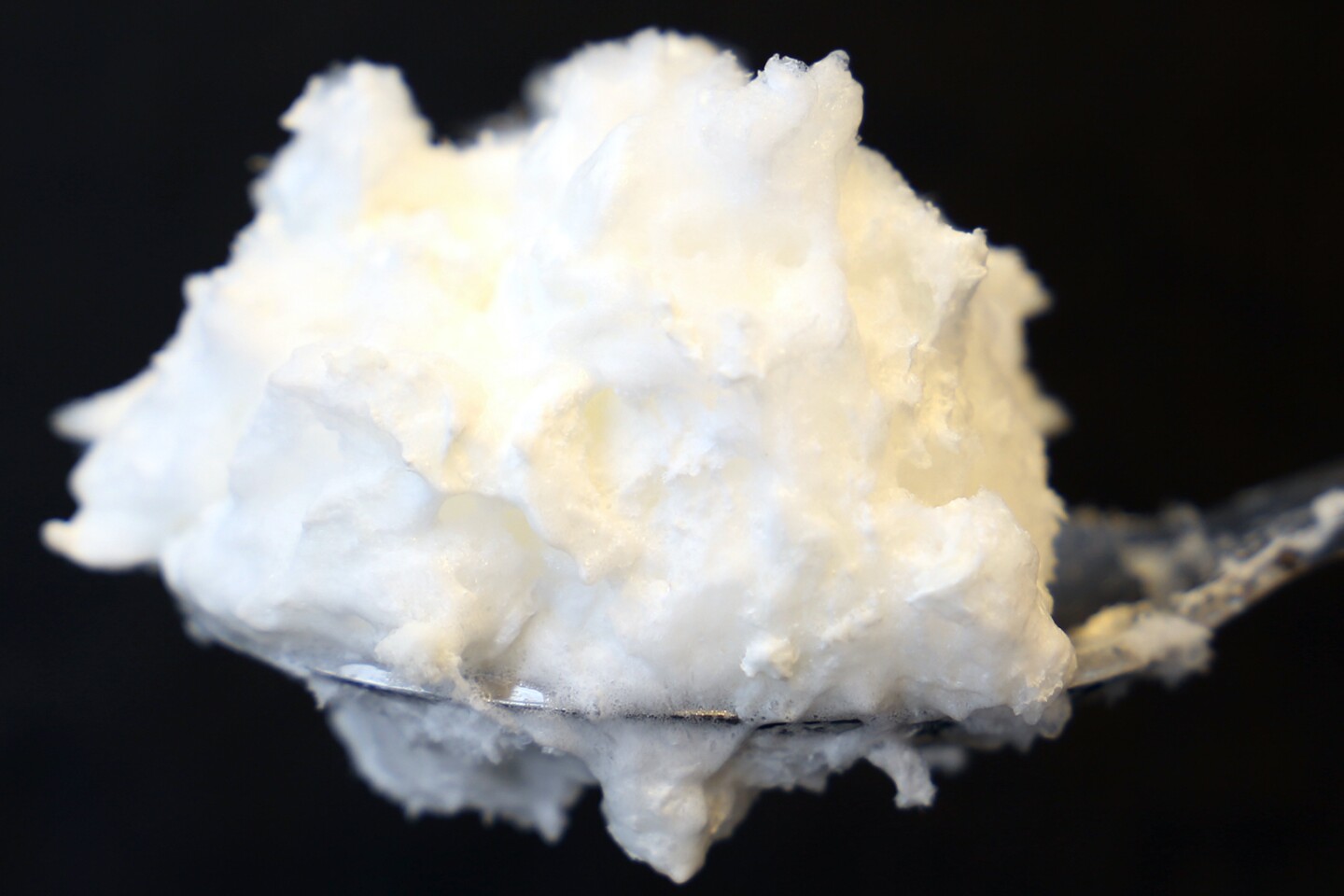

Stage 2, the shavings are gathered to the center and a second screw moves them vertically into the snow tank. Next, while the shaving is happening, water is fed from a tank to the ice conditioner to rinse the ice. Dirty water is collected in front with a squeegee and vacuumed and filtered and returned to the tank. Finally, clean water from the ice making tank is delivered to the ice through a pipe which distributes it evenly across the ice.

The following video shows the Zamboni in action:

Zamboni.com provided the following “Evolution of the Zamboni Ice Resurfacer”: