Hygiene and the elimination of pests and fungus is a major problem when it comes to the growth and storage of bulk crops in modern agriculture. From the preparation of the buildings used for food production to the silos containing the mass storage of products, cleanliness is essential in ensuring the quality of the produce.

Applying various chemicals extends the life of the products, even when produce is being put into storage.

Agrochemical specialists, Stored Crop Conservation Limited (SCCL), have created a system of “fogging” these storage spaces with a very fine mist which guarantees the whole volume is coated with the appropriate chemical.

Over time, by developing its own equipment and methods, SCCL figured out a way to get a much more even treatment than conventional methods. The chemicals used are often regulated substances, and careful control of the application volume is absolutely critical.

Since SCCL knows how essential the chemical dispersal process is, for nearly 15 years the company has utilized Titan flow meters to record the amount of chemical used.

Trevor Forster, Managing Director of Titan Enterprises, has been involved with agrochemical flow measurement since back in the early 1970s.

Having been involved in developing flow metering solutions for that same industry on and off since then, Forster has a simple answer when asked why flow meters work so well in the crop conservation business.

“The use and deposition of powerful agrochemicals is critical for a safe and effective spread. Metering the actual volume used against a known enclosed volume (a building), or a known acreage (a field), is vital. Historically, users would have to check what they used after it had been sprayed or dispersed and not during the process,” he says.

In regards to problems that arise when it comes to accurately recording the volume of dispensed chemicals, Forster adds, “Many of the fluids are extremely aggressive and the volumes dispensed can often be quite small requiring a combination of chemical resistance and low flow rates to ensure precision. This is Titan’s specialty area.”

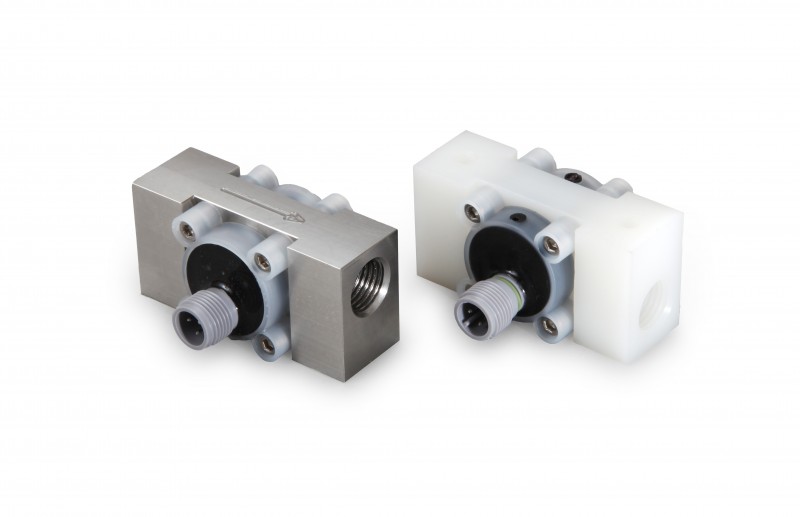

On current generation SCCL machines, the volume of dispensed chemicals is recorded using Titan 900 series mini-turbine flow meters. These flow meters are coupled to a panel indicator recording total volume throughput on a re-settable display.

“Titan’s 900 series mini-turbine flow meter is a very compact meter manufactured in 316 stainless steel and PVDF with Viton seals. Not only can the 900 series satisfy the flow and chemical resistance parameters, it is easy to install in a cabinet,” says Forster.

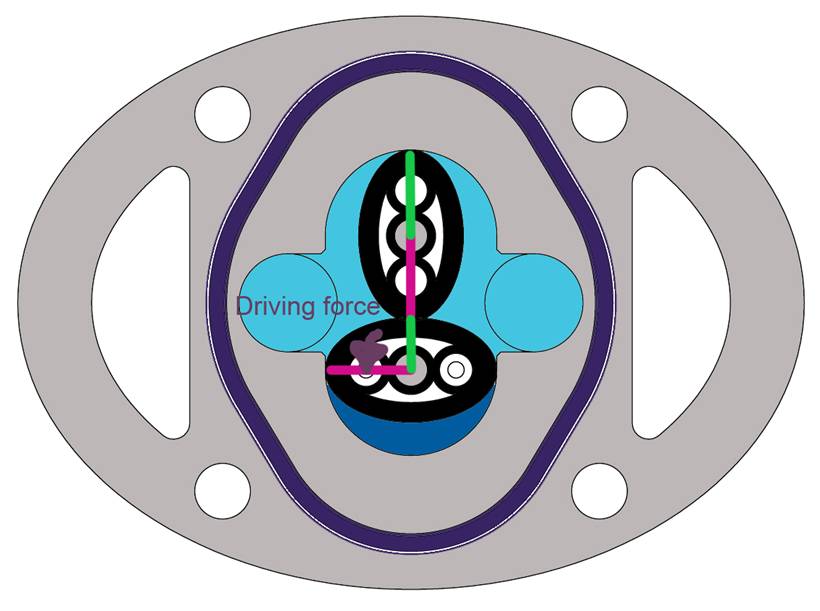

The panel indicator gives the machine operator the ability to check the desired dosage for an area against the actual volume of chemical used thereby ensuring safe dispersal of the controlled chemicals. In addition, SCCL’s in-house calibration rigs utilize Titan’s highly accurate oval gear (OG) flowmeters to make sure consistent, reliable measurements always take place.

Forster concluded, “Many of the chemicals SCCL uses are controlled substances, meaning recording their application is important to the company’s quality guarantees. For some time, Titan re-calibrated SCCL’s meters every year, but they wanted to bring this facility in house, so a transfer standard flow meter appeared to be an ideal solution. Now, we certify that meter once a year and SCCL calibrate their other Titan Enterprises flowmeters in-house, saving down time and money in the process. Titan’s oval gear meters are positive displacement devices where a swept volume of fluid is passed with each rotation of the gear. They are very efficient as the pressure imbalance across the chamber that drives the gear is high, even at low flows. The clearances around the gears are tight, giving good accuracy, and making them ideal for this type of transfer calibration.”

For further information on flowmeter systems for precise measurement of small volumes of dispensed agrochemicals, or other regulated chemicals, please visit www.flowmeters.co.uk or contact Titan enterprises on +44-1935-812790 / trevor@flowmeters.co.uk.

The Author:

Trevor Forster, M.D of Titan Enterprises, has been involved with developing innovative flow metering solutions for over 40 years. He may be contacted on trevor@flowmeters.co.uk