Metrology is known as the interface between science and manufacturing; leading manufacturers worldwide depend on it to translate engineering designs into mass products. Any tweak or change to a manufacturing process must have its foundation in the measurement of current equipment and processes.

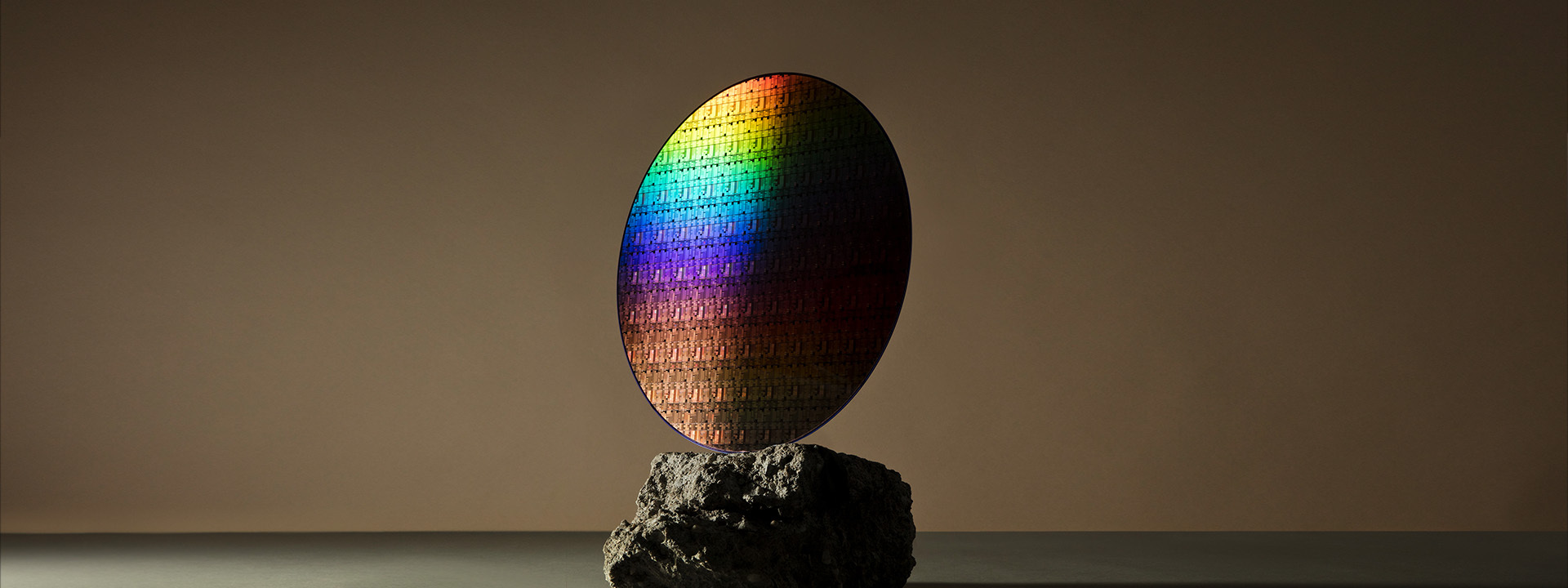

Say you are an aerospace manufacturer and need to analyze the complex curves of airfoils of large turbine blades; these are the curved surfaces that provide the ratio of lift to drag as a plane flies. Or say you are an automobile manufacturer and are experiencing regular production downtime due to high levels of wear and tear on probes used to measure the size and shape of camshaft bearings. Or say you are an electronics manufacturer. You need equipment to check the height of semi-conductor wafers and LCD glass thickness. Finally say you design cell phone casings, something each of us carries every day; when producing these casings by the millions, manufacturers need probes to check the geometry of the casing and other formed parts before assembly. Solartron Metrology (SM) designs and manufactures a wide range of products to solve these engineering challenges.

SM, part of the Ultra Precision Technologies division of UK’s Ametek, is a world leader in the manufacture of precision linear measurement solutions where reliability and accuracy are paramount. Producing digital and analog dimensional gauging probes, displacement transducers, optical linear encoders and control systems, SM exports 90% of its products to leading aerospace, automotive, electronics and manufacturing concerns worldwide.

SM manufactures all critical components in-house to the most exacting standards and works primarily with OEMs, systems integrators and end-users. SM’s R&D group works cooperatively with customers to continually improve its products and to meet increasingly complex measurement and control application standards.

SM Orbit Digital Gauging Probe Measuring System

The SM Orbit Digital Gauging Probe measuring system is fast, taking up to 4,000 readings per second, per probe, and is an easy way to network dimensional and positional measuring transducers together. SM takes a modular approach to the design and integration of measurement and control systems so they can be put together quickly, easily and cost effectively.

Transducer types can be mixed and matched on a single network with one common interface regardless of sensor technology. Third-party products such as temperature and strain sensors and air gauges can also be networked.

All system components are available including sensors, electronics, cabling, interfaces and software drivers. Orbit integrates directly with PLCs, PCIs, USB and RS232 for all common programming languages and software including LabVIEW, Microsoft Windows, and Excel.

Orbit is simple and flexible and this makes it the most respected platform for powerful and cost-effective deployment.

Pencil Style Gauging Probes

SM is the world’s leading manufacturer of analog and digital pencil style gauging probes with either spring, vacuum or pneumatic operation. SM’s gauging probes are built to withstand the harsh environments of shop floors but provide the precision required in a test laboratory. The ultra high tolerance bearings manufactured in-house provide exceptionally long life type tested to over 13 million cycles. The titanium core carrier is inert and able to withstand lateral shock. A multi chambered coil helps improve efficiency by increasing the gain is the core moves through the coil. The cables polyurethane sheath and foil screening give superior electrical and mechanical properties and excellent chemical resistance. Retract versions enable fast and safe automatic gauging.

Touch probe tips have been designed to gauge delicate surfaces and a wide range of probe tip services and materials are available. SM probes can be combined to measure just about any application available. Standard probes are complemented by special transducer ranges and ensure that taking precision measurements of miniature parts, bores, and cavities is a simple and reliable process. Gauging probes include Bluetooth compatibility, have ergonomic grips, and are light weight.

Displacement transducers

SMproduces market-leading miniature and larger displacement transducers are produced with stainless steel casings and fittings and hermetically sealed versions are available for submersible applications or chemically hostile environments.

To consolidate their range of digital and analog transducers SM produces an extensive choice of instruments and electronics including a diverse range of numerical displays and controllers as well as high-performance signaling condition modules. SM products can be used in laboratories, on the shop floor or in the field and provide precise linear measurements, quality control, test and measurement, and machine control.

Exact measurements are essential to efficient and safe commerce. Correct measurements help manufacturers to monitor, change and improve production processes.

Related articles on IndustryTap:

- Global Demand Expanding for High-Precision Dimensional Metrology Equipment

- Non-Contact Sensors Boost Productivity, Cut Downtime, Reduce Expenses by 40% a Year

- New Sensors Help Detect, Flush Out Criminals

References and related links: